In a groundbreaking study led by Prof. Ye Hong from the University of Science and Technology of China, a research team has developed a cutting-edge alumina ceramic bionic wick inspired by the stomatal array of natural leaves. The research, published in Langmuir, addresses the growing challenges posed by the increasing power consumption of electronic chips as their performance continues to improve.

Challenges in Cooling Strategies

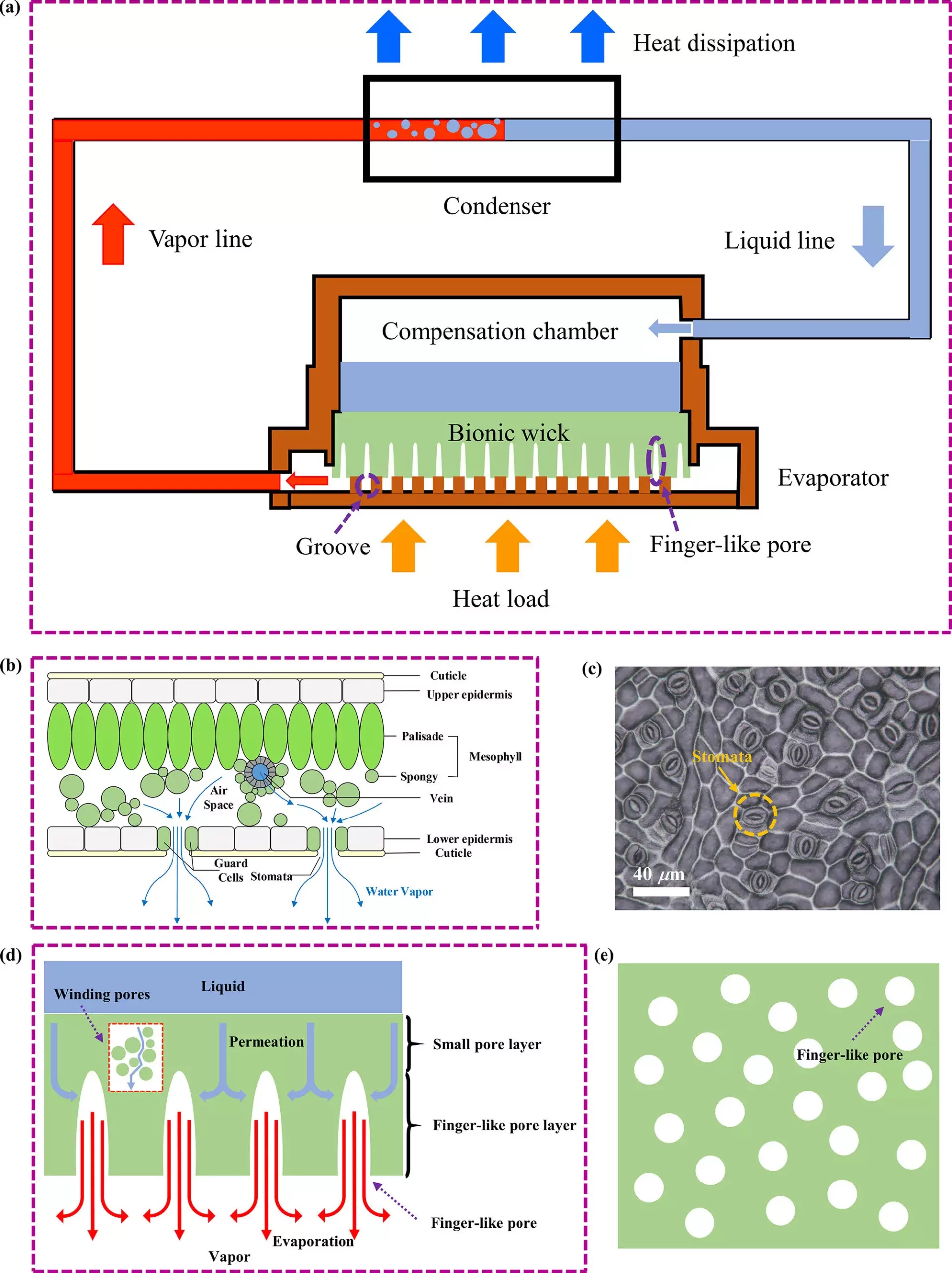

The evolution of electronic chips has led to higher power consumption, necessitating more effective cooling solutions. One of the promising methods for cooling electronic chips is the use of loop heat pipes (LHPs), known for their high heat transfer capability, antigravity heat transfer, and lack of moving parts. However, designing the pore structure of the capillary wick within an LHP presents a significant challenge due to the conflicting requirements for flow resistance and capillary force.

To tackle this design dilemma, Prof. Ye Hong’s team turned to nature for inspiration, specifically the stomatal structure of plant leaves. By employing phase inversion tape casting, the research team successfully created an alumina ceramic bionic wick with finger-like pore structures. These unique pores, similar to the stomata of leaves, significantly increase the gas-liquid interface area, enabling efficient expulsion of gaseous working fluids and reducing mass transfer resistance.

Superior Performance

The micron-sized pores surrounding the finger-like structures provide ample capillary force for liquid replenishment at the gas-liquid evaporation interface. Start-up and operation tests of the LHP with the bionic wick confirmed its superior heat and mass transfer performance. The innovative design not only resolves the conflict between enhancing capillary force and reducing flow resistance but also presents a novel solution for cooling high-power-density electronic chips.

The development of this alumina ceramic bionic wick has significant implications for efficient thermal management in various industries, including aerospace, aviation, and microelectronics. The novel design offers a promising solution for addressing the cooling challenges posed by high-performance electronic chips, paving the way for enhanced heat dissipation and improved overall performance in electronic devices.

Leave a Reply