As the global demand for portable energy solutions continues to surge, the resulting environmental implications create an urgent need to reevaluate traditional battery technologies. Conventional lithium-ion batteries are widely known for their high energy density and efficiency, yet they rely on fluorinated compounds for their construction—materials that pose significant environmental and health risks. Characteristics such as non-biodegradability and the toxic byproducts of chemical degradation, particularly hydrogen fluoride (HF), highlight the unsustainability of current battery systems. The scientific community faces a dual challenge: not only must new battery technologies achieve high performance, but they must also meet escalating environmental regulations aimed at reducing hazardous substance use.

Recent breakthroughs by researchers at POSTECH and Hansol Chemical aim to address these challenges head-on by introducing a new class of battery materials that are devoid of fluorinated substances. The study, highlighted in the Chemical Engineering Journal, unveils a novel non-fluorinated electrolyte solution and binder that complies with anticipated restrictions from governing bodies such as the European Union, which is expected to implement a ban on per- and polyfluoroalkyl substances (PFAS) by 2026.

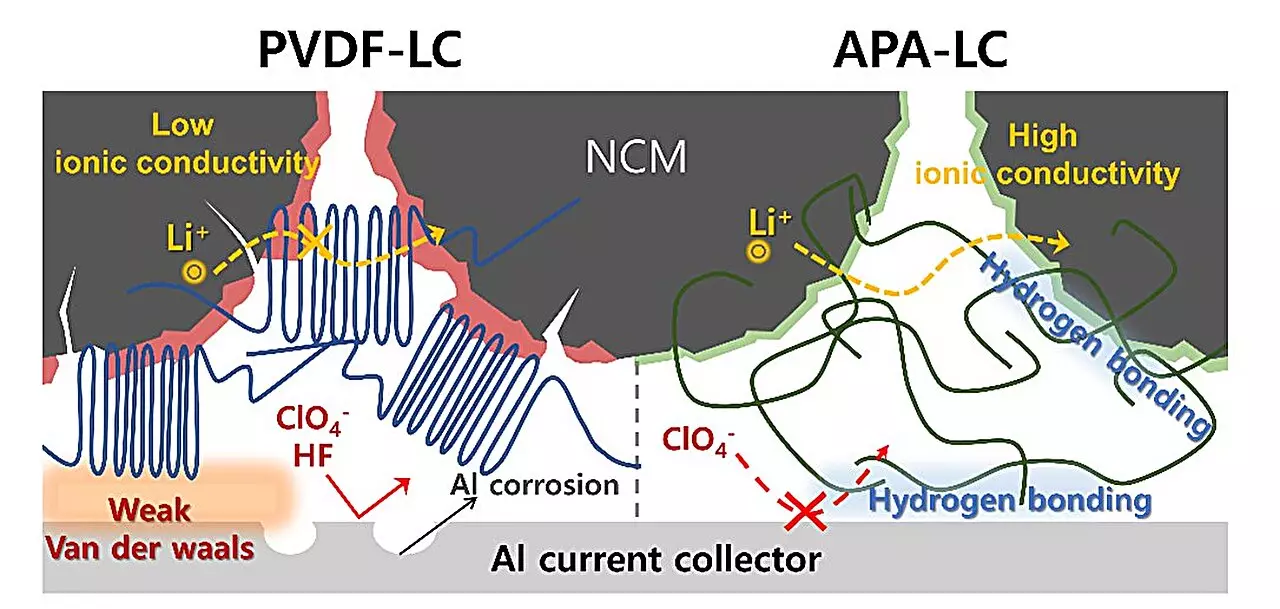

The innovative system introduces lithium perchlorate (LiClO4) as an electrolyte while pairing it with an aromatic polyamide (APA) binder. This combination replaces the traditional polyvinylidene fluoride (PVDF) and lithium hexafluorophosphate (LiPF6) that dominate current battery designs, subsequently reducing the environmental impact without compromising performance. Importantly, this move signifies progress toward a sustainable lithium-ion battery landscape.

The APA-LC battery system presents numerous advantages over previous configurations. The aromatic polyamide binder exhibits exceptional bonding capabilities, effectively securing the cathode’s active materials to the aluminum current collector. This is critical in mitigating the risk of electrode corrosion that can occur in the electrolyte, which extends both the life and reliability of the battery system itself. Furthermore, the electrolyte’s unique composition, richly infused with lithium chloride (LiCl) and lithium oxide (Li2O), strategically lowers the energy barrier for ionic transfer. This promotes rapid lithium diffusion, optimizing the battery’s output performance and overall efficiency.

Conducting comparative tests showcases the APA-LC system’s prowess, demonstrating superior oxidation stability and an impressive 20% retention of capacity over 200 cycles at high charge/discharge rates. These quick yet thorough evaluations were conducted in coin cell formats within the voltage range of 2.8 to 4.3 V, underscoring the system’s robust capabilities in practical applications.

The culmination of this research is the successful manufacturing of a high-capacity 1.5 Ah pouch cell, capable of maintaining excellent discharge profiles while demonstrating resilience during rapid charging. This achievement highlights the potential for scalability in the use of entirely non-fluorinated materials, paving the way for a new era in battery manufacturing practices.

Professor Soojin Park of POSTECH articulated the impactful nature of this innovation, stating, “We haven’t just replaced fluorinated systems; we’ve proven high-capacity retention and outstanding stability. Our solution will advance the sustainability of the battery industry, facilitating the shift to non-fluorinated battery systems while ensuring environmental compliance.” With these promising results, the shift toward greener technology is not merely desirable but achievable.

Managing Director Young-Ho Yoon from Hansol Chemical emphasizes the commercial potential of this development, indicating that the secondary battery market is projected to reach KRW 1.7 trillion by 2026. With a forward-thinking approach to research and development, Hansol Chemical aims to solidify its position in the environmentally-conscious materials sector.

As the world strives toward sustainability, innovations like the APA-LC battery system signify a pivotal moment in battery technology. By championing eco-friendly materials devoid of fluorinated compounds, this research not only aligns with regulatory trends but also sets a new standard for energy storage solutions. The collaboration between academic and corporate entities heralds a future where efficiency and environmental safety coexist, driving responsible progress in the battery industry.

Leave a Reply