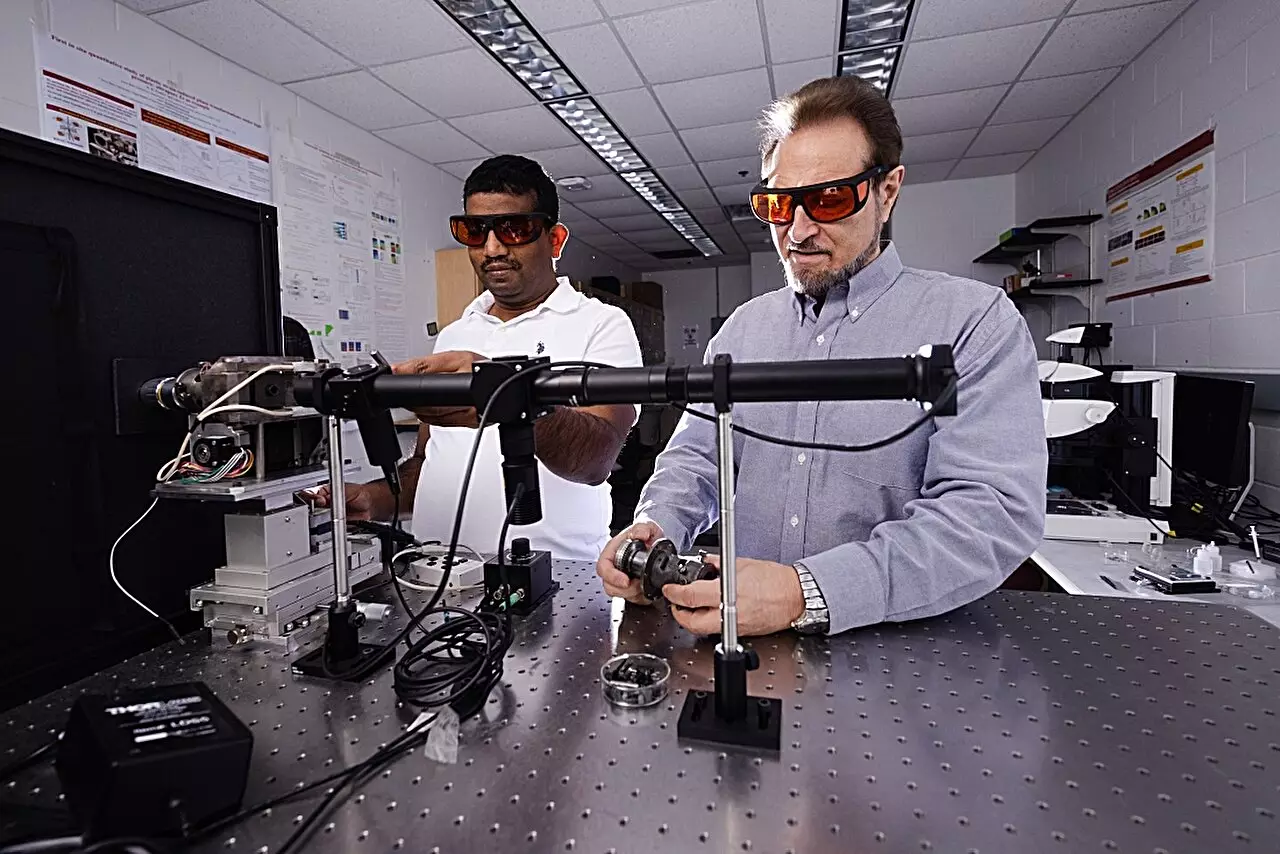

Valery Levitas, a renowned engineer and professor at Iowa State University, has been at the forefront of material science research for over two decades. His journey began in 1999 when he transitioned from Europe to the United States, bringing with him a revolutionary tool known as the rotational diamond anvil cell. This sophisticated apparatus is designed to apply high pressures and shear forces to materials, allowing researchers to observe the intricate changes that occur at a microscopic level. These changes not only validate theoretical predictions but also open doors to new discoveries in the properties of materials, particularly how these properties evolve under extreme conditions.

The primary focus of Levitas and his group’s research is to unravel the complexities of crystal structures and their transformations. By using this advanced tool, they can investigate how materials alter their physical characteristics under varying conditions of pressure and shear—key factors that influence their usability in various industrial applications.

Recently, Levitas and his team published significant findings regarding silicon, a pivotal material in the electronics industry. Their research reveals that silicon exhibits unique phase transformations when subjected to substantial mechanical deformation. Specifically, they discovered that silicon undergoes a conversion from its “Si-I” crystal structure to the “Si-II” phase at 0.3 gigapascals pressure, a remarkable reduction from the previously understood threshold of 16.2 gigapascals.

The implications of this discovery are substantial. For years, researchers have concentrated on how silicon reacts to high-pressure environments, but Levitas’s team has introduced a new variable—plastic shear deformation. This addition to their experiments allows for a dialogue between pressure and deformation that had been largely ignored, providing insights that could lead to innovative applications in electronic materials.

The traditional approach to studying material behavior under high pressure often deters practical applications, as working with extreme conditions can be cumbersome and economically unfeasible. However, the innovations presented by Levitas and his colleagues demonstrate that utilizing lower pressures through plastic deformation can yield factors of pressure reduction by as much as 54 times when transforming silicon’s phases. This breakthrough not only simplifies the experimentation process, but it also lays the foundation for practical industrial applications of high-pressure material properties without the associated challenges.

Levitas clearly emphasizes that the research’s goal is less about simply altering the physical dimensions of materials but rather about manipulating their microstructures. Such changes can fundamentally alter a material’s properties, which is critical when aiming to utilize silicon in new, technology-driven contexts.

Implications for the Industry

The practical applications of these findings extend toward industries that rely heavily on silicon, such as electronics and optics. The ability to obtain nanostructured materials or mixtures that possess optimal electronic, optical, and mechanical characteristics is a compelling prospect for the future of technological development. Industries often face obstacles with traditional high-pressure techniques; hence, the possibility of achieving similar outcomes through more manageable methods could incentivize the adoption of the approaches championed by Levitas’s team.

Furthermore, the discovery that the microstructural changes can facilitate the formation of new material phases opens avenues for research into novel materials with enhanced properties. This intersection of advanced mechanics, physics, material sciences, and applied mathematics paves the way for a deeper understanding of materials, leading to innovative solutions to many modern engineering challenges.

Valery Levitas’s research represents a significant advancement in material science, challenging preconceived notions about high-pressure study practices. By focusing on the impact of plastic shear deformation on silicon and its phase transformations, Levitas and his collaborators are not only expanding the horizons of academic inquiry but also laying the groundwork for practical industrial applications. As they continue to explore this uncharted territory, the potential for discovering new materials with tailored properties could have transformative effects on numerous technology sectors. The future indeed looks promising for material science, and the innovative approaches introduced by Levitas and his team will undoubtedly shape its trajectory.

Leave a Reply