As electric vehicles and portable electronic devices continue to surge in popularity, the quest for higher energy density in lithium-ion (Li-ion) batteries has led researchers to focus on materials like NCM811 (nickel-cobalt-manganese oxide). While these materials promise enhanced performance due to their superior capacity, they are not without their challenges. One significant concern is the poly-crystalline structure of NCM811, which can develop cracks under stress. These microfractures compromise the integrity of the material, leading to accelerated loss of active components and ultimately reducing the battery’s life cycle. Addressing the chemo-mechanical evolution of these materials is crucial not only for longevity but also for maximizing energy efficiency.

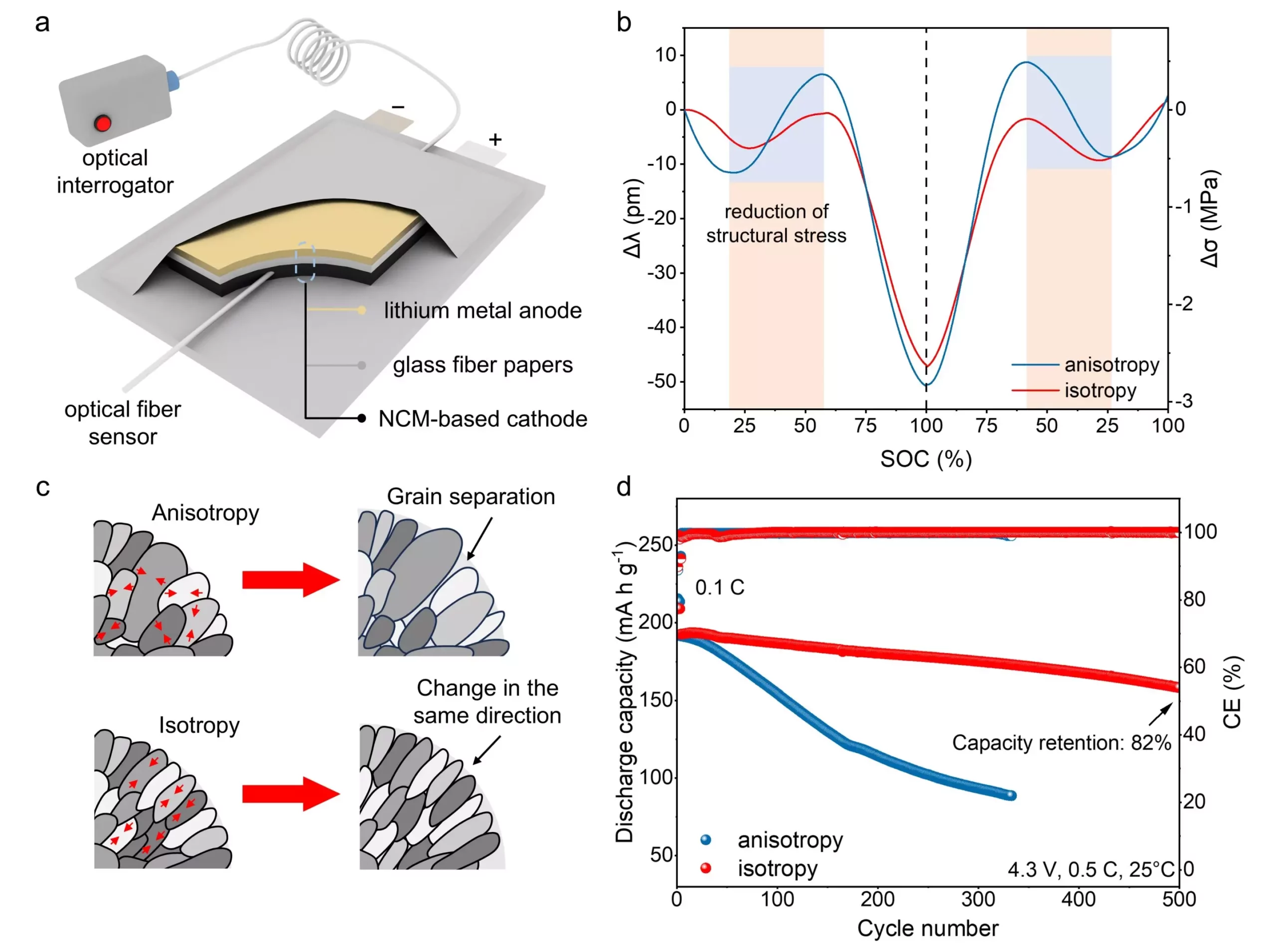

Understanding the mechanisms behind stress evolution in battery materials is vital to overcoming performance limitations. Research led by Prof. Yunhui Huang and Prof. Zhen Li has made significant strides in this area utilizing optical fiber technology to monitor the stresses at play in NCM811 cathodes during battery operation. This innovative approach allows for real-time observation of the chemo-mechanical dynamics without substantially altering battery functionality. By embedding an optical fiber within the battery structure, the team can detect changes in stress that can lead to undesirable cracking, providing invaluable data that would typically be challenging to gather.

In their research, the scientists distinguished between two primary types of stress affecting the NCM811 material: chemical and structural. Chemical stress arises naturally from the (de)lithiation process, an integral part of how batteries operate. While unavoidable, understanding its implications is crucial. In contrast, structural stress poses a more significant threat as it directly contributes to crack formation, jeopardizing battery efficiency and lifespan. It appears that variations in the crystal structure during the lithium-ion exchange process—specifically, alternating patterns along the c-axis—engender this harmful structural stress.

Combatting the detrimental effects of structural stress is essential for enhancing NCM811 cathode performance. Prof. Huang and Prof. Li’s research points to the potential for improving the anisotropy of primary particles within the poly-crystalline framework. By creating an ordered arrangement of the particles, they propose a method that mitigates the structural stress responsible for crack formation. Experimental results demonstrated that when properly arranged, the poly-crystalline material could achieve superior structural stability and deliver an impressive capacity retention of 82% even after 500 charge-discharge cycles at a rate of 0.5C.

This pioneering work not only provides a detailed understanding of the chemomechanical evolution in NCM811 materials but also holds broader implications for battery technology as a whole. Optical sensing is emerging as a vital tool for monitoring battery health and performance, which can direct future materials development efforts. As highlighted by Prof. Huang, the incorporation of such advanced sensing technologies promises to revolutionize the manufacturing of safer, more efficient batteries, ensuring the future sustainability of energy storage solutions. Consequently, ongoing research in this field will likely pave the way for technologies that meet the increasing demands for energy density and longevity in the dynamic market of electric energy solutions.

Leave a Reply