Fluidic technologies are integral to modern society, significantly influencing fields such as healthcare, pharmaceuticals, biology, and chemical engineering. The ability to manage fluids with precision is paramount; however, researchers have persistently faced the challenge of creating efficient platforms that allow for the seamless, switchable capture and release of various liquids. This article delves into a groundbreaking technology developed by researchers at The Polytechnic University of Hong Kong (PolyU), which promises to transform fluidic manipulation.

A significant advancement in fluid handling is embodied in the ‘Connected Polyhedral Frames’ (CPFs). This innovative research, led by Professor Wang Liqiu and detailed in a recent publication in *Nature Chemical Engineering*, showcases how CPFs enable reversible and programmable liquid processing capabilities. The visionary approach taken by Dr. Zhang Yiyuan, who spearheaded this research, illustrates how materials can work in harmony to manage fluids effectively.

In stark contrast to solid manipulation—where precision is already highly developed—the handling of liquids presents a range of problems. For instance, when fluids interact with solid surfaces, they tend to spread, leading to inefficiencies in transfer, inaccuracies in volume control, and potential cross-contamination of samples. This challenge is particularly pronounced in the use of disposable plastics like pipettes, which contribute to global plastic waste. CPFs offer a new paradigm for addressing these issues by facilitating reversible switching between the capture and release of fluids while minimizing contamination and enhancing overall efficacy.

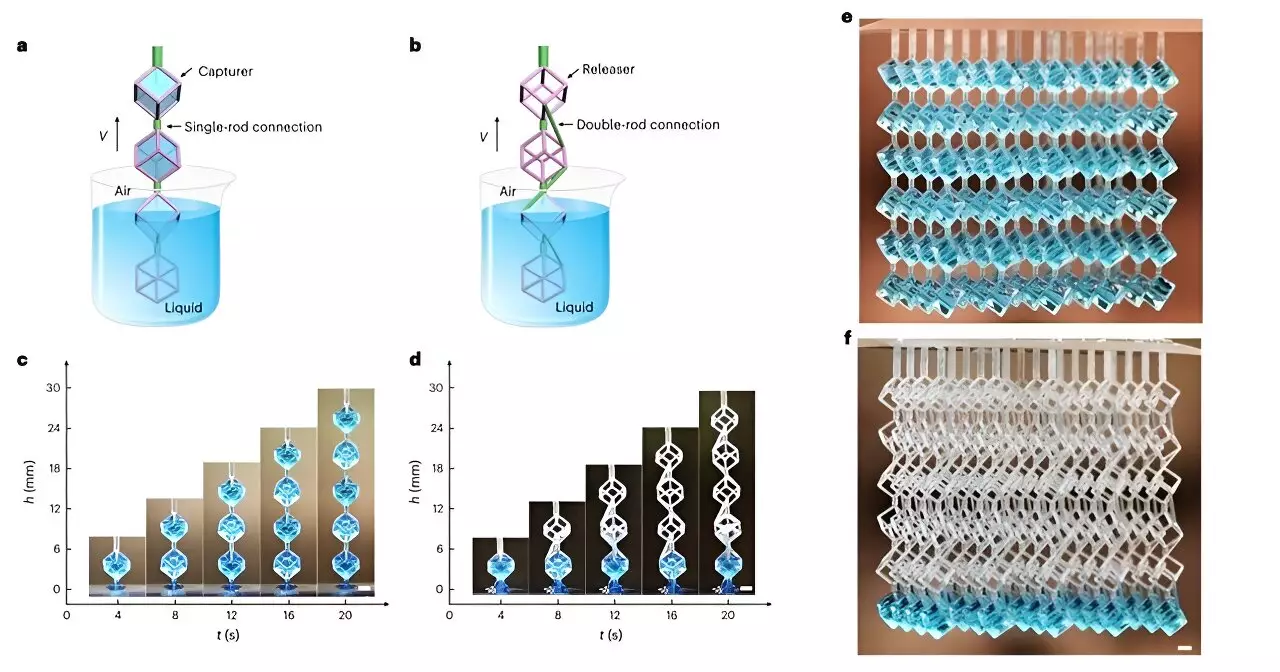

CPFs stand out due to their unique structural configuration. The designs consist of frames that either capture fluids or release them, depending on their configuration and connection type. When operating under specific conditions, CPFs can form channels that allow for precise control over liquid release. This transformative capability stems from a novel approach that leverages the dynamics between the fluid and the structural components of the CPFs.

The technology enables researchers to manipulate liquids in a versatile and controlled manner, including 3D programmable liquid patterning, spatiotemporal control of liquid concentrations, and even packaging for large-scale liquid manipulation. Remarkably, CPFs are versatile enough to handle a variety of liquid types—from aqueous solutions to organic solvents—allowing for a broad range of applications across multiple industries.

A notable demonstration of CPFs’ capabilities is found in their application for controlled drug delivery systems. The research team effectively utilized CPFs to create a network for the 3D patterning of vitamins B2 and B12, encapsulating them in biocompatible hydrogels. By manipulating the gel membrane’s thickness, the team achieved controlled release rates, showcasing CPFs as a promising tool for pharmaceuticals that require precise dosing.

Comparatively, traditional sampling methods like cotton and flocking swabs demonstrate significant shortcomings with sample residue; however, CPFs have shown a marked improvement in release efficiency due to their structured design. When employed to detect the influenza virus, CPFs outperformed existing methods, underscoring their potential for use in rapid diagnostics.

Further showcasing CPFs’ advantages, the researchers investigated using them for the encapsulation of microbial cells, which could revolutionize how biological materials are processed. The efficient separation of bacteria from reaction products simplifies processes and increases yield, indicating that CPFs could set new benchmarks for microbial engineering.

Beyond healthcare and biological applications, the implications of CPFs stretch into environmental technology. The research team has experimented with a commercial-scale humidifier prototype that outperforms traditional models in terms of water storage and energy efficiency. Additionally, CPFs have been found to enhance gas absorption capabilities, presenting new opportunities for processes such as carbon capture and storage.

The potential of CPFs as a meta-metamaterial—operational regardless of the liquids being handled or the materials used in their construction—paves the way for various future inventions and applications. This technology is not just an improvement over existing fluidic systems but might emerge as a fundamental shift towards sustainability and efficiency in fluid handling.

The innovation of CPFs represents a significant leap forward in fluidic technologies, making liquid management more precise, efficient, and environmentally conscious. The collaborative efforts of Dr. Zhang Yiyuan and Professor Wang Liqiu offer hope for a future where fluid manipulation is no longer cumbersome, but rather a streamlined process that can address pressing challenges across multiple fields. The ongoing research in this area not only sets a new standard in fluidic processing but also stimulates further advancements in materials science and engineering.

Leave a Reply