Electric vehicles (EVs) are increasingly viewed as a crucial component in the global drive toward sustainable energy solutions. However, one significant barrier to their widespread adoption is the need for advanced battery technology capable of supporting prolonged and efficient operation. This is where structural batteries come into play — a groundbreaking innovation that merges traditional battery functions with components that contribute to the structural integrity of vehicles.

Structural batteries are designed to serve dual purposes: they not only store energy but also contribute to the vehicular structure, which can lead to significant reductions in weight and increased efficiency. Unlike conventional batteries, which occupy space and add weight, structural batteries are integrated directly into the materials that make up the vehicle’s architecture. This integration can result in vehicles that are lighter and more energy-efficient, allowing electric vehicles to extend their range while mitigating the challenges of traditional battery design.

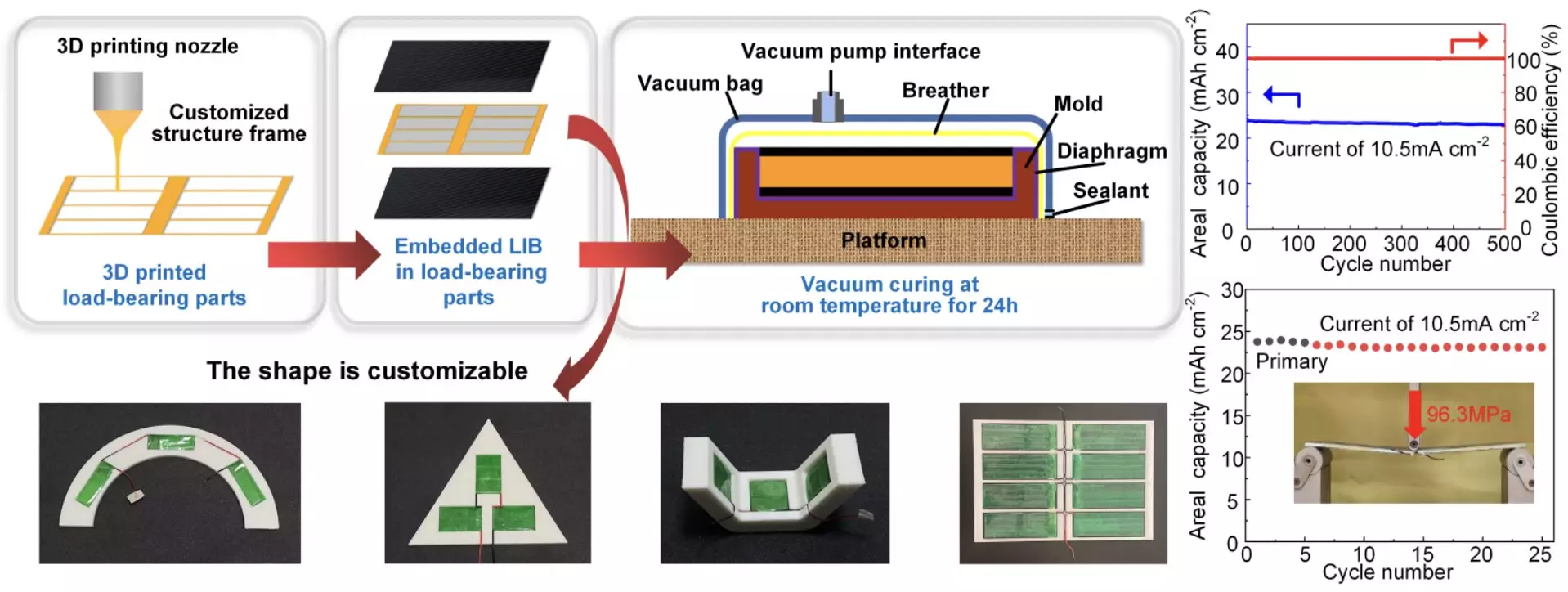

Researchers from Shanghai University have made significant strides in the realm of structural batteries, focusing on improving their performance through innovative fabrication methods. Their research, published in Composites Science and Technology, emphasizes the use of 3D printing technology. By leveraging this method, the researchers can create structural lithium-ion batteries that are customizable in geometric configuration, thus enhancing both energy storage and load-bearing capabilities.

The advent of 3D printing has revolutionized manufacturing, enabling rapid prototyping and customized solutions. In the realm of structural batteries, this technology allows researchers to design and produce structural frameworks that serve as the primary load-bearing elements. By decoupling the energy storage unit from the structural framework, the design minimizes the mechanical stress on the battery materials during operation, which can significantly enhance performance.

Yinhua Bao, the lead author of the study, articulates that the development prioritizes high energy density while ensuring structural integrity. The researchers have chosen advanced electrode materials and electrolytes to improve the energy density and lifespan of their batteries. Their approach could yield tremendous benefits for various applications, particularly in electric vehicles and robotic systems, where efficiency and durability are paramount.

While previous attempts at creating structural batteries have shown promise, they often faced limitations, including low energy densities and poor mechanical cycling performance. The innovative 3D printing strategy employed by Bao and his colleagues addresses these issues head-on. Through their research, they have demonstrated the potential for high-performing structural batteries that maintain their functionality under stress. Their tests reveal impressive metrics, such as a high energy density of approximately 120 Wh/kg and remarkable durability after numerous operational cycles.

Through the use of finite element analysis, the research team could simulate stress scenarios and optimize the structural framework design. This preemptive approach to potential failure points allows for the production of batteries that can withstand significant load without compromising their energy storage capacity. The results of their study underscore the viability of structural batteries for a broad range of applications, from electric vehicles to autonomous robots and beyond.

The possibility of applying this novel technology to various sectors could spark a wave of innovation within the energy storage market. The structural batteries developed through this research are not limited to transportation; their customizable nature means they can be adapted for use in aerial drones, medical devices, or any application requiring efficient and lightweight power sources. As the demand for sustainable energy solutions grows, the potential for large-scale manufacturing of these structural batteries could meet the increasing need for high-performance energy storage systems.

Furthermore, the adoption of structural batteries aligns with the global shift toward more sustainable practices. By integrating energy storage solutions into the very fabric of vehicles and devices, industries can produce lighter and more efficient products, thus reducing their carbon footprint and improving energy utilization.

As researchers continue to refine their techniques and expand on the applications of structural batteries, we may see a substantial impact on the electric vehicle market and beyond. The next stage involves exploring potential uses in unmanned aerial vehicles and other robotic systems, pushing the boundaries of what structural energy storage can achieve.

The work being done by Bao and his team exemplifies the promise of innovation in sustainable energy solutions. With further exploration and application, structural batteries have the potential to redefine energy storage paradigms and contribute significantly to a more sustainable and efficient future. As the industry evolves, these groundbreaking technologies may very well lead us into an era of unprecedented energy efficiency and sustainability.

Leave a Reply