In various industrial processes, the separation of gases is a critical task that influences both efficiency and cost. From the medical realm—where pure oxygen is crucial for patient care—to environmental initiatives such as carbon capture, the demand for effective gas separation technologies has never been more pressing. However, traditional methods often fall short due to their high energy consumption and inherent limitations. As the need for sustainable practices grows, the search for innovative solutions in gas separation has gained momentum.

A common scenario involves cooling air to extreme temperatures to liquefy it, followed by a slow reheating process to facilitate the separation of nitrogen and oxygen. This method is not only energy-intensive but also financially burdensome, provoking an urgent call for more efficient techniques. This scenario highlights a dichotomy in the industry: the urgent need for gas separation versus the old, energy-heavy methodologies that have been employed.

The Challenge of Rigid Materials in Gas Separation

Historically, gas separation technologies have relied heavily on rigid porous materials designed for specific gases. While these materials provide precise control over the gas separation process, their inherent rigidity limits the range of gases that can be effectively filtered. This specificity can result in inefficiencies when dealing with a diverse array of gases. The challenges compound when industries seek flexibility in operations, prompting researchers like Wei Zhang from the University of Colorado Boulder to explore a new avenue for gas separation technologies.

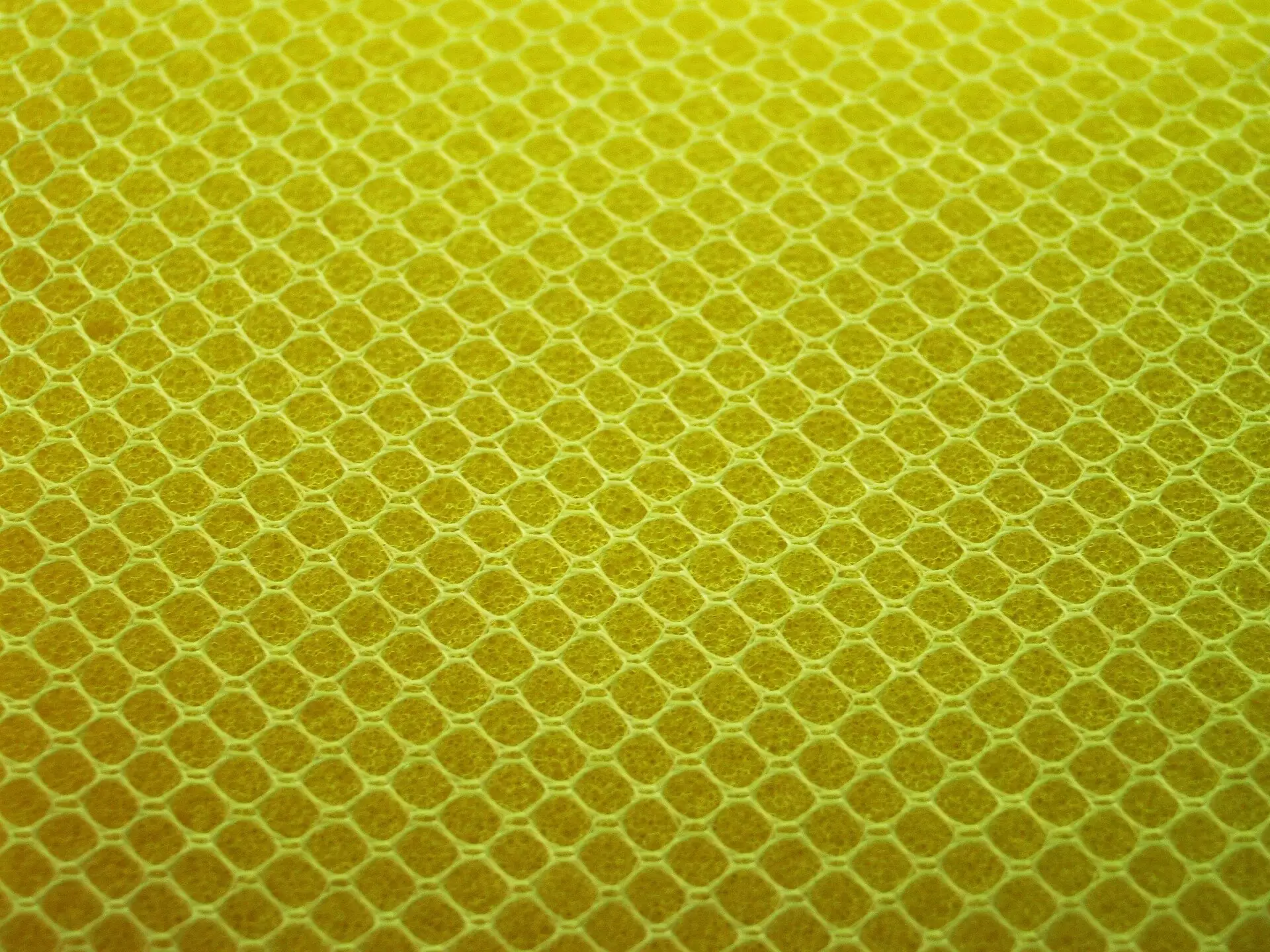

Zhang and his research group have made significant strides in developing a new kind of porous material that combines rigidity with flexibility. This innovative approach allows for dynamic adjustments in pore size, accommodating a wider range of gases and facilitating size-based separation with markedly lower energy costs.

Innovation through Versatile Porous Materials

The novel material crafted by Zhang and his team employs flexible molecular linkers within a predominantly rigid framework. As temperatures fluctuate, the oscillation of these linkers dynamically alters pore sizes, enabling the material to adapt to different gases effectively. In practical terms, this means that when exposed to varying temperatures, the material can allow smaller gases, like hydrogen, to pass through, while restricting larger molecules based on controlled conditions.

This adaptability addresses a glaring inefficiency in conventional gas separation methods, wherein materials often become obsolete when confronted with gases outside their specific design parameters. Thus, Zhang’s research contributes not only to enhanced efficiency but also to a broader scope of applicability across different industries.

The Chemistry Behind the Breakthrough

The creation of this versatile porous material draws on principles of dynamic covalent chemistry, particularly focusing on boron-oxygen interactions. By employing a dynamic bond that can break and reform, the researchers have created a framework that exhibits self-correcting behavior. This variability is vital for crafting materials that can be fine-tuned for specific industrial needs.

The research journey was not without hurdles; understanding the structure of the material initially proved challenging. Yet, through empirical exploration and the examination of small-molecule model systems, the team successfully elucidated the packing and bonding mechanisms within their material, leading to a breakthrough in design conceptualization.

Scalability and Future Applications

A crucial aspect of Zhang’s research resonates with scalability. The materials developed are not only made from readily available and cost-effective building blocks, but the processes for their production are designed with industrial-scale applications in mind. As companies increasingly seek to reduce costs while improving efficiency, the incorporation of scalable technologies in gas separation becomes an enticing prospect.

The implications of such a development extend beyond mere efficiency. With potential applications in membrane-based technology, Zhang’s materials could lead to even more sustainable solutions, significantly lowering overall energy requirements in gas separation processes. In a world grappling with climate change and the realization of finite resources, this innovative shift provides a promising pathway towards sustainability.

Through this exciting research, the prospect for a future where gas separation is efficient, cost-effective, and environmentally conscious moves closer to reality. Indeed, the journey toward optimizing gas separation reflects an intersection of chemistry and real-world application, demonstrating how science can pave the way for transformative change.

Leave a Reply