In recent years, the exploration of biomimetic materials has garnered significant attention, inspired by the complex and resilient structures found in nature. Among these, sea sponges stand out due to their remarkable ability to balance strength and flexibility through a layered and patterned design. This deep-seated connection between biological systems and material science sheds light on revolutionary techniques in creating synthetic materials that not only mimic nature but also surpass its capabilities in terms of applicability and functionality.

The resilience of biological systems lies within their unique architectural compositions. Sea sponges, which grow through layered structures, exemplify how integrating various materials—both rigid and soft—can result in superior durability. Nancy Sottos, a leading researcher in the field from the Beckman Institute, emphasizes that nature intelligently utilizes “intricate patterning” to turn seemingly brittle materials into highly robust structures. By imitating these natural strategies, scientists are able to unlock potential breakthroughs in crafting synthetic polymers.

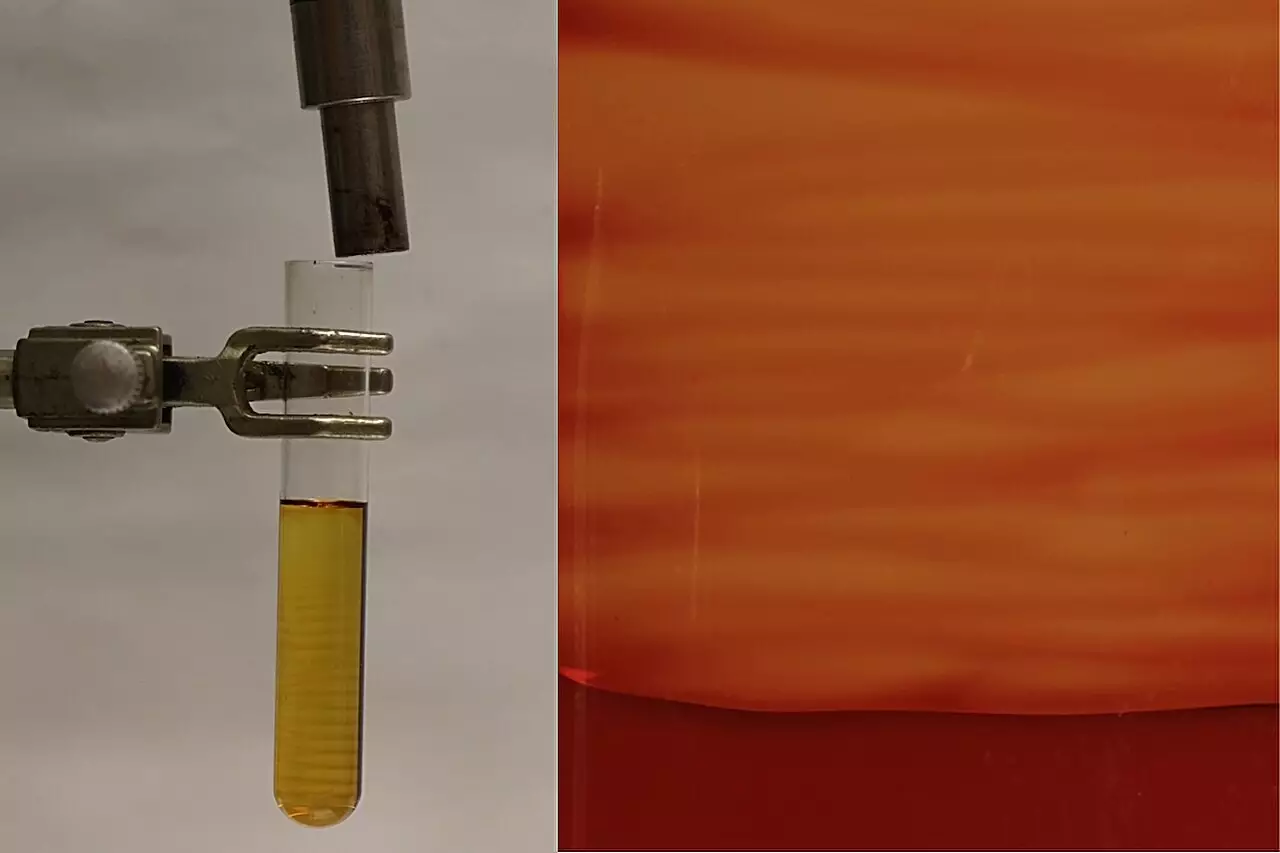

Sottos, along with her team, has conducted extensive research which has unveiled a process called frontal polymerization— a method where heat instigates a chemical reaction to yield polymers. This bioreceptive approach, as demonstrated in their 2021 research, facilitated the creation of materials inspired by biological structures. More importantly, their recent study has expanded the scope of this technique, allowing for the deliberate design of crystalline patterns within polymers to amplify both their toughness and longevity.

Traditionally, the manufacturing of synthetic materials has relied heavily on meticulous and controlled techniques. Jeff Moore, a pivotal contributor to this research, notes that while nature employs spontaneous processes to create complex patterns, the synthetic material landscape has been characterized by a rigidity in production methods. The development of morphogenic manufacturing techniques marks a significant departure from these norms, as researchers can now induce structural changes simply by modifying chemical reactions.

The effort required to optimize these reaction conditions was no small feat; it involved extensive experimentation over weeks. Justine Paul, the lead author of the study, reflects on the gratifying journey of observing the spin-mode dynamics and their effects on the microstructure of the materials. This achievement resulted in a novel polymer featuring both amorphous and crystalline regions, promoting outstanding toughness that blends both rubbery flexibility and rock-solid strength.

The caliber of this research cannot be overstated, as it emerged from a rich collaboration among experts from varied scientific disciplines within the Beckman Institute. Cecilia Leal, specializing in materials science, employed advanced X-ray scattering techniques to probe the orientation of polymer chains, providing crucial insights into how these interactions define the resultant material properties. Such integration of chemical, mechanical, and materials science expertise is what propels innovation in this domain.

Aerospace engineering professor Philippe Geubelle’s involvement focused on modeling the process. By harnessing an understanding of thermo-chemical instabilities, Geubelle aided in illuminating the mechanisms behind the creation of these heterogeneous materials. The deliberate merging of experimental work with theoretical modeling showcases the critical nature of collaborative efforts in fulfilling the ambitions of complex projects.

The achievements underscored by this research signify more than just an advancement in material science; they suggest an evolutionary jump towards new classes of materials that possess unique properties unattainable through traditional manufacturing processes. Moore underscores the importance of the collaborative environment at the Beckman Institute, which serves as a breeding ground for breakthroughs.

These developments in biomimetic materials will likely pave the way for new applications across various fields, including aerospace, biotechnology, and construction, ultimately leading to innovations that not only enhance performance but also adhere to the sustainable methodologies inspired by nature. As researchers continue to delve into the intricacies of how natural systems operate, the potential for developing synthetic materials that can adapt, endure, and thrive seems boundless.

Leave a Reply