Plastic pollution has emerged as one of the most critical environmental challenges of our time. With millions of tons of plastic waste produced annually, effective recycling methods are urgently needed. Among the various forms of plastics, polyethylene terephthalate (PET) stands out for its widespread use in both textiles and packaging materials. However, traditional recycling methods often prove inefficient, particularly in terms of chemical recycling where plastics are reprocessed into their original raw materials. Without effective solutions, the accumulation of plastic waste will continue to pose severe threats to ecosystems and human health.

A recent study spearheaded by Professor Kotohiro Nomura of Tokyo Metropolitan University presents an exciting advancement in the field of chemical recycling. The research focuses on the depolymerization of PET using a novel method that involves alcohols and an accessible iron trichloride catalyst. This innovative approach facilitates the breakdown of polyester, enabling it to revert to its original materials without the need for harsh acidic or alkaline processes, which have historically defined conventional recycling methods.

The significance of this research cannot be overstated. Conventional depolymerization often demands high temperatures and substantial quantities of aggressive chemicals, making the process not only costly but also environmentally damaging. In contrast, the methodology introduced by Nomura’s team is both cost-effective and environmentally friendly, aligning with the global push for sustainable waste management practices.

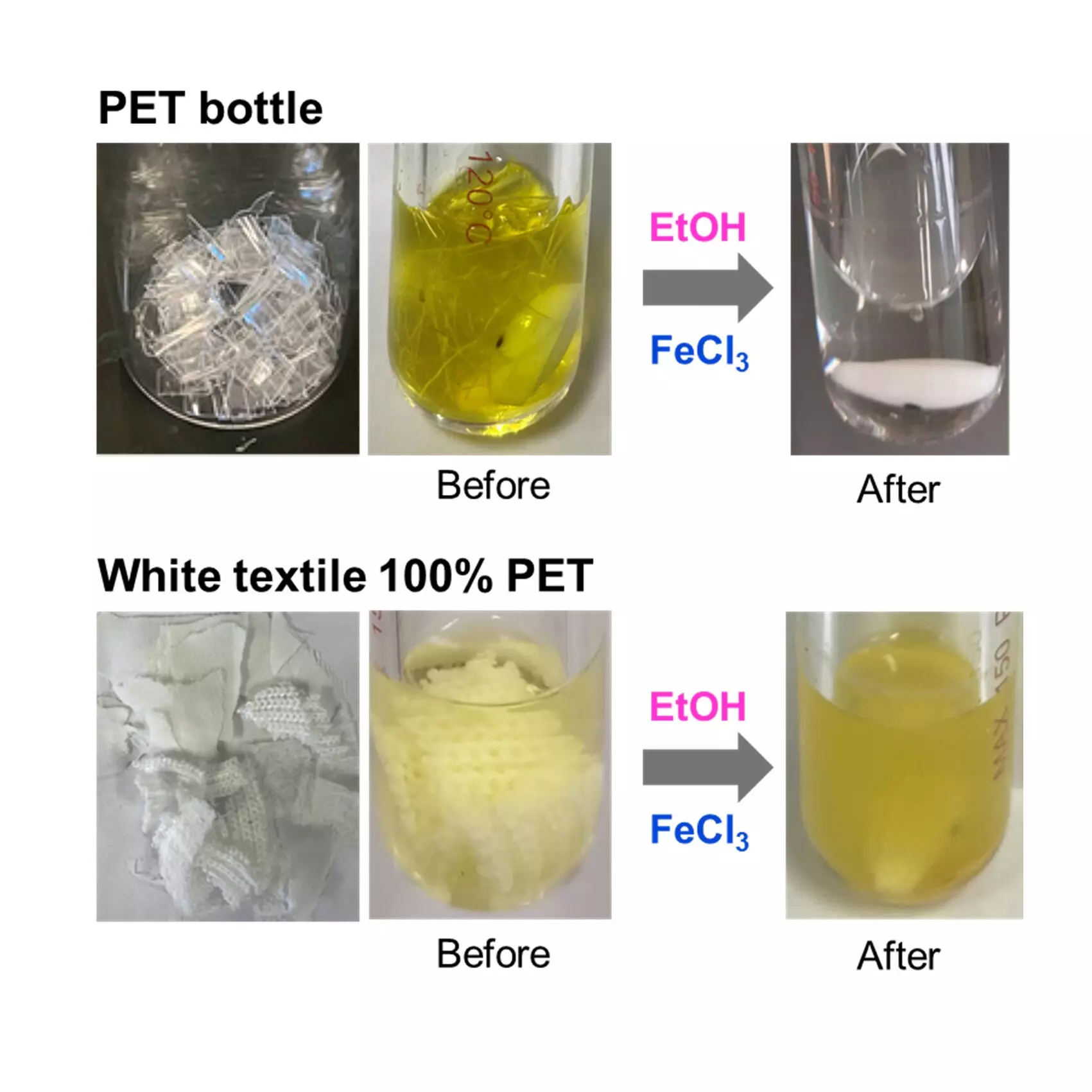

The team’s breakthrough method employs ethanol in combination with iron trichloride (FeCl3) or iron bromide (FeBr3) as catalyzers, achieving remarkable selectivity in depolymerization. The findings indicate that the process yields diethyl terephthalate (DET) and ethylene glycol (EG) at an impressive rate of 98-99% selectivity, showcasing the catalytic efficacy of inexpensive iron compounds. Remarkably, this method not only applies to PET bottles but also facilitates the selective removal of PET from textile waste, which frequently includes a blend of polyester and cotton.

This process allows for the quantitative recovery of cotton along with the production of DET and EG, which can then be repurposed in various industries. The research thus presents a dual benefit: addressing plastic waste issues while simultaneously allowing the reuse of valuable textile fibers.

The implications of this research stretch far beyond academic interest. By providing a straightforward means for selective PET depolymerization, the team at Tokyo Metropolitan University contributes to the larger narrative of achieving a circular economy. This model emphasizes reducing waste, extending product life cycles, and converting discarded materials back into usable resources.

As demand for sustainable solutions rises amidst growing environmental concerns, innovations such as this method could redefine the landscape of plastic waste management. Professor Nomura’s research holds promise not only for industries reliant on PET but also for global efforts to mitigate the environmental impacts of plastic pollution, potentially revolutionizing recycling practices worldwide.

This novel approach to PET depolymerization represents a beacon of hope for sustainable waste management and highlights the essential role of research in tackling pressing environmental issues.

Leave a Reply