In a groundbreaking achievement, a research team spearheaded by James Tour at Rice University has unveiled an innovative technique to recycle critical metals from electronic waste (e-waste). This advancement not only promises to enhance the efficiency of metal recovery processes but also aims to mitigate the environmental repercussions typically associated with traditional recycling methods. The significance of this discovery lies in its potential to alleviate the escalating demand for raw materials, ultimately leading to reduced mining activities, deforestation, and pollution.

The increasing volume of electronic waste is a global concern, presenting challenges in both environmental sustainability and resource management. Current recycling practices, such as hydrometallurgy and pyrometallurgy, are often problematic. They are energy-intensive and generate harmful byproducts, including toxic waste and acidic residues that further exacerbate environmental degradation. The Rice University’s research seeks to address these issues directly, providing an alternative that could reshape the landscape of waste management.

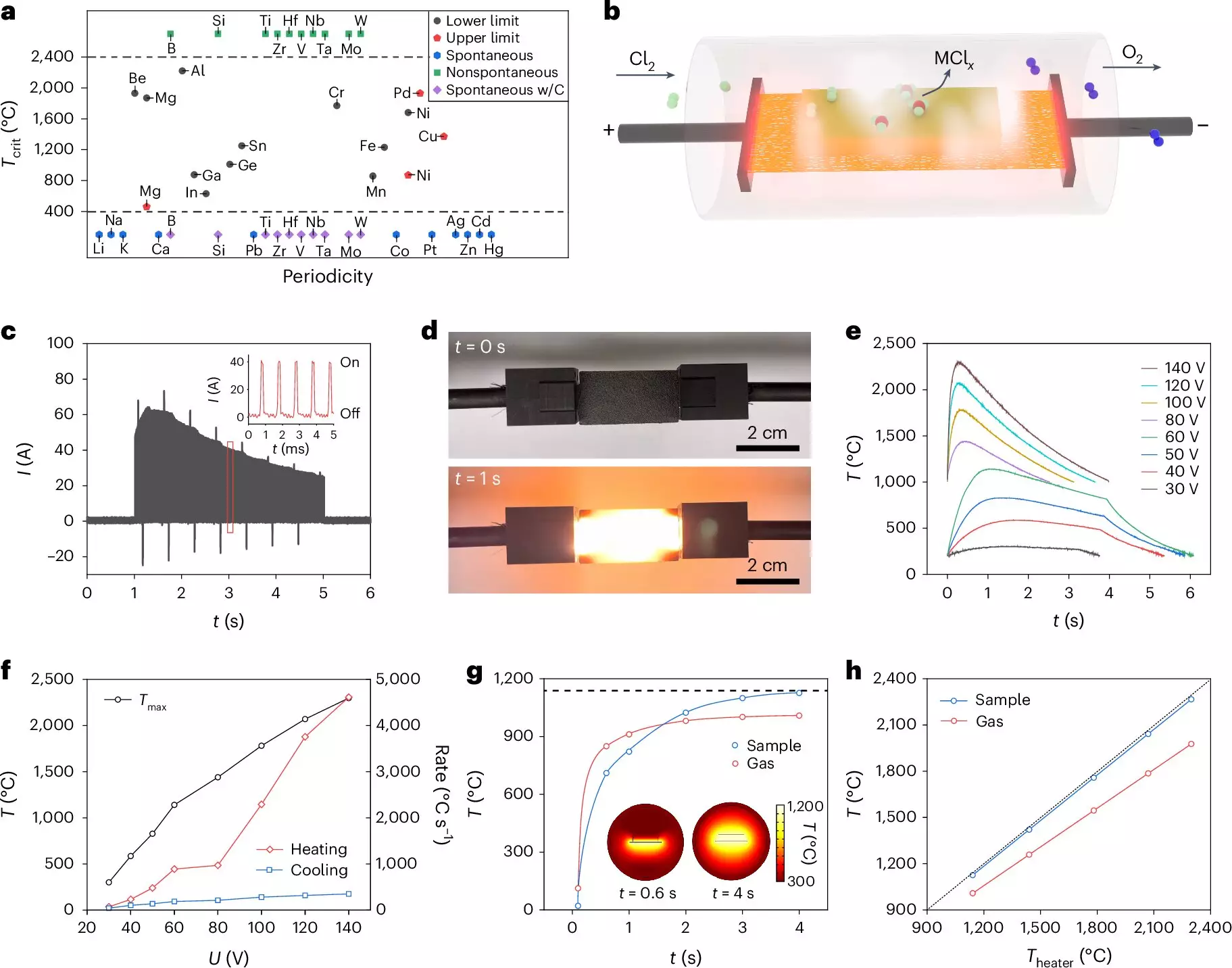

The method introduced by Tour’s team is built upon his previous research involving flash Joule heating (FJH). This innovative process involves the application of an electric current to rapidly elevate the temperature of materials, allowing for efficient transformation and extraction of valuable metals such as gallium, indium, and tantalum. By employing chlorination and carbochlorination processes, the team has crafted a way to achieve precise temperature control and swift metal separation without relying on harmful solvents or excessive water usage.

One of the standout features of this new recycling technique is its impressive results: the recovery process demonstrated a metal purity exceeding 95% and a yield rate surpassing 85%. Such efficiency speaks volumes about the potential for large-scale implementation and the possibility of further refining the method for additional metals, including lithium and rare Earth elements. Essentially, this technological leap could serve as a model for future recycling initiatives aimed at recovering critical materials from waste streams.

This research has far-reaching implications beyond just metal recovery. With critical metal shortages becoming more pronounced, the need for economically viable and environmentally friendly recycling methods has never been greater. Shichen Xu, a co-author of the study, emphasized that this breakthrough not only addresses immediate resource scarcity but also creates economic incentives for recycling industries globally. By streamlining the recovery process, communities and businesses can engage more effectively in sustainable practices.

The work conducted by James Tour and his team positions Rice University at the forefront of sustainable engineering and circular economy initiatives. Their innovative recycling technique represents a pivotal step towards minimizing environmental impacts while harnessing the value of e-waste. As the world grapples with resource limitations and ecological concerns, advancements like this are essential in paving the way toward a more sustainable future, reinforcing the importance of research in the stewardship of our planet’s resources.

Leave a Reply