Green hydrogen has emerged as a beacon of hope in the quest for sustainable energy solutions, heralding a potential transformation in our approach to carbon emissions. As the U.S. Department of Energy pushes towards the ambitious goal of net-zero carbon dioxide emissions, the urgency to develop economical and efficient methods of producing hydrogen from renewable sources has never been greater. One of the most exciting developments in this field is the recent innovation in electrolyzer technology, specifically aimed at optimizing the splitting of water molecules into hydrogen and oxygen gas.

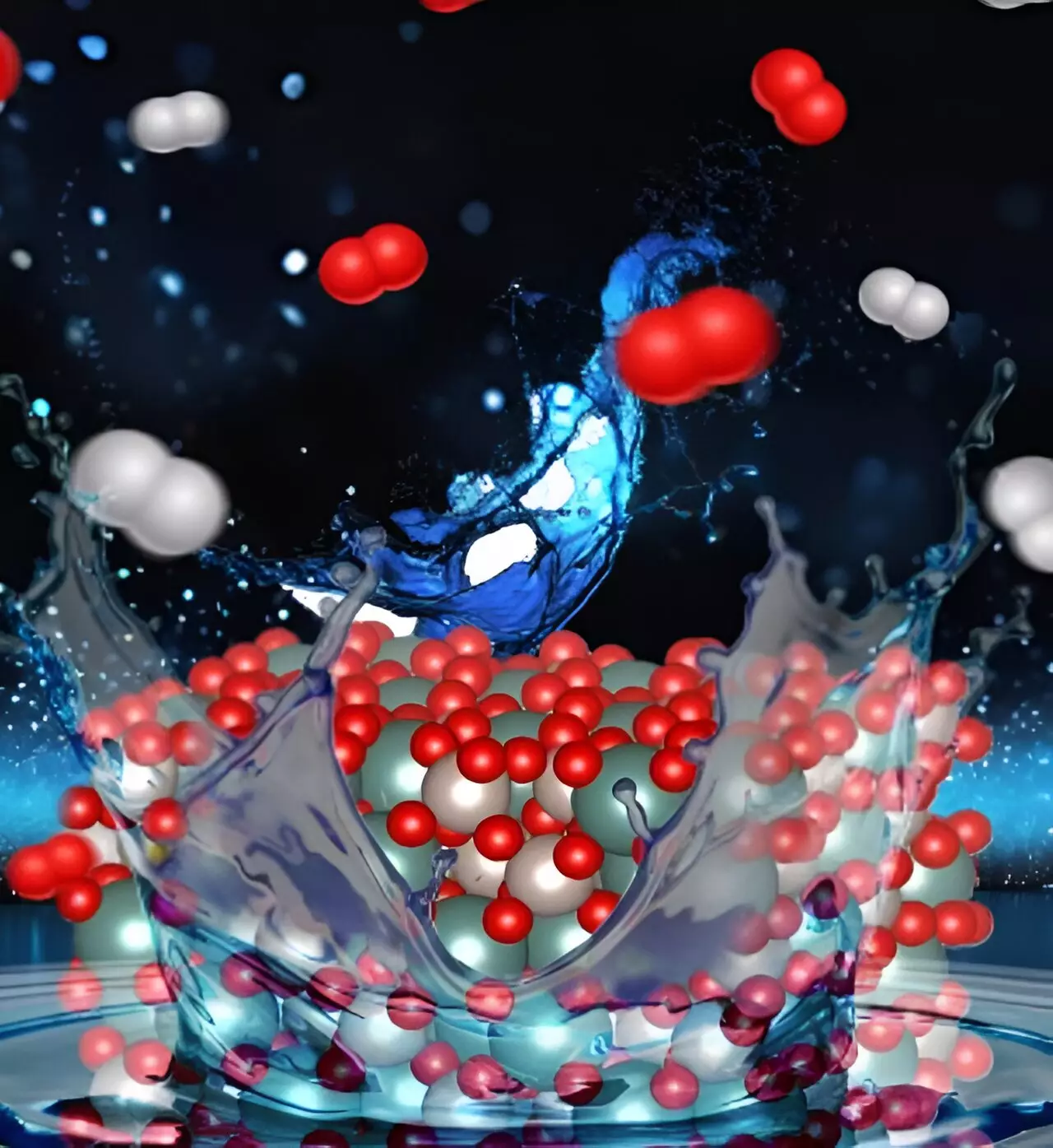

The process of creating green hydrogen lies in the electrochemical reactions facilitated by devices such as proton exchange membrane electrolyzers. This technology harnesses electricity, often sourced from solar or wind energy, to disassemble water into its elemental components. Although this process holds tremendous potential, the balancing act between hydrogen and oxygen production remains a significant bottleneck. With hydrogen generation speeding ahead while oxygen production lags, researchers have been challenged to innovate ways to enhance the overall efficiency of this crucial reaction.

Defect Engineering: A Game Changer

A pivotal development emerged from a groundbreaking study published in the Journal of the American Chemical Society. Under the leadership of Professor Hong Yang, a team of interdisciplinary researchers has tapped into the concept of “defect engineering,” a strategy commonly employed in semiconductor manufacturing, to significantly enhance the performance of electrocatalysts used in the electrolyzer process. By intentionally introducing imperfections into a catalyst material, the team has paved the way for a novel approach to improving catalytic efficiency.

In this research, the team utilized ruthenium to create a complex oxide electrocatalyst structured like pyrochlore. This innovative design didn’t simply aim for perfection; instead, it thrived on the introduction of yttrium atoms at reactive sites within the ruthenium base. The deliberate creation of ‘defects’ in the otherwise perfect crystal lattice is reminiscent of strategies deployed in computer chip technology, highlighting a striking parallel between the fields of chemistry and electronics.

A Deeper Understanding of Electrocatalyst Behavior

The significance of this research extends beyond merely boosting hydrogen production. It offers critical insights into the theoretical and practical aspects of how electrocatalysts operate. The researchers found that by replacing specific ruthenium atoms with yttrium, they could amplify the rate at which oxygen gas is generated, directly addressing one of the key challenges for electrolyzer technology. This method fostered not only higher production rates of green hydrogen but also offered a clearer picture of the intricate balance between the electronic properties of the materials involved.

Graduate student Bidipta Ghosh, a pivotal figure in the study, emphasized how their observations challenged earlier assumptions in the field: rather than increasing the concentration of oxygen in their material, the team discovered that changing the oxidation states of ruthenium was the driving factor behind improved activity. This nuanced understanding underscores the often-overlooked intricacies present in material science, reinforcing the idea that scientific advancement often hinges on the smallest details.

A Collaborative Effort in Science

The success of this research was not merely the product of individual genius but a testament to the power of collaboration across different scientific disciplines. Professor Yang pointed out that the combined expertise in areas ranging from chemical engineering to materials science was integral to navigating the technical challenges presented during their work. This interdisciplinary approach demonstrates a growing trend in the scientific community toward converging knowledge bases, fostering innovation through diverse perspectives.

By dissecting the electronic changes in ruthenium at the atomic level, the research team illustrated how trace amounts of yttrium can turn a previously suboptimal material into a potent catalyst for efficient hydrogen production. This achievement not only brings us closer to realizing a reliable and sustainable green hydrogen economy but also opens a dialogue on the potential ramifications of innovative engineering solutions in tackling broader energy issues.

Implications for the Future of Energy

The advancements achieved through this study are promising, suggesting a shift in how we can approach the grand challenge of producing green hydrogen affordably and efficiently. With the looming threat of climate change, harnessing renewable energy through methods like defect engineering in electrocatalysts positions us at the forefront of effective solutions. As industries strive for carbon neutrality, the implications extend far beyond mere technical achievements; they encompass a holistic shift toward sustainable practices that could redefine our energy landscape.

The journey toward realizing the full potential of green hydrogen is complex, but with pioneering research and inventive engineering techniques lighting the way, the path forward is brighter than ever.

Leave a Reply