In the era of rapid technological advancement, the question of sustainability looms large, particularly in the field of electronics where integrated microelectronic devices are prevalent. These modern marvels are not only complex but also notoriously difficult to repair and recycle, contributing significantly to electronic waste. Amid these challenges, researchers are exploring innovative solutions to incorporate sustainability within this high-tech realm. One compelling advancement has come from a recent publication in Angewandte Chemie, where a team of scientists has developed a new class of debondable adhesives that promise to revolutionize how we think about repairs and recycling in the electronics industry.

The inherent design of many microelectronic devices makes them poorly amenable to repair. With the rate of technological obsolescence outpacing our ability to recycle, electronic waste is becoming an overwhelming environmental issue. The shift towards a circular economy—a model that emphasizes resource sustainability, waste reduction, and efficient recycling—has never been more urgent. Adhesives play a pivotal role in the assembly of electronic devices, yet their present forms often hinder the disassembly and recycling processes. Enter debondable adhesives, inspired by nature’s genius—specifically, the adhesive capabilities of mussels.

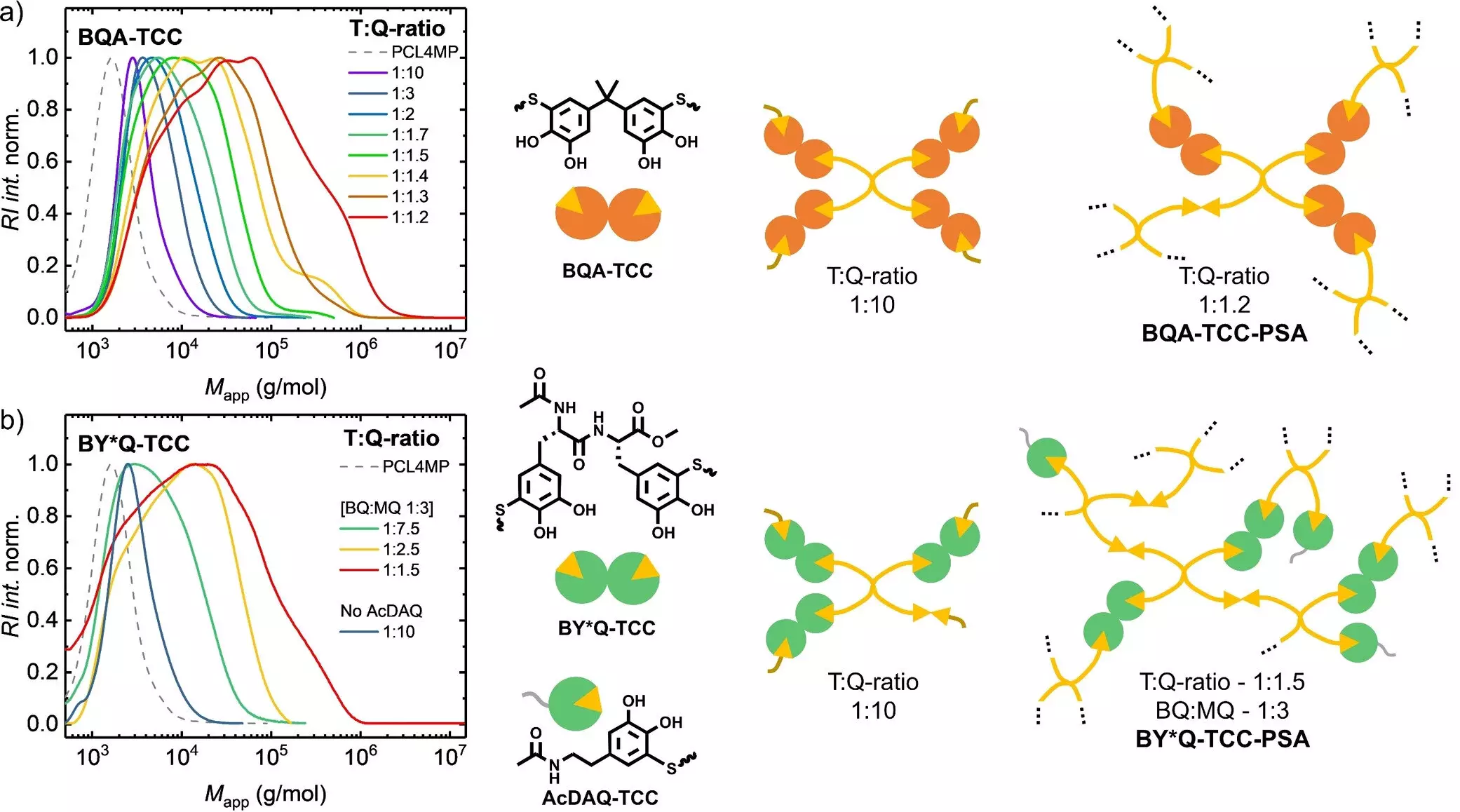

Mussels possess exceptional adhesive qualities that allow them to adhere to rocky surfaces in turbulent aquatic environments. Utilizing this natural phenomenon, a research team led by Kannan Balasubramanian, Hans Börner, and various collaborators from top institutions has engineered new adhesive formulations that can be deactivated on command. Their work rests on the novel use of thiol-catechol polyaddition, which successfully combines specific molecular structures that endow these adhesives with their unique properties.

At the core of their innovation lies the transformation of catechol groups into quinones through a simple oxidation process. This transformation drastically reduces the adhesion strength, allowing for the effortless removal of the adhesive from surfaces. The reaction’s reversibility not only offers user-controlled adhesion properties but also represents a significant advancement towards creating materials that seamlessly integrate into repair and recycling paradigms.

Within this groundbreaking research, the team has drawn comparisons between biobased adhesives derived from peptidic biscatechol precursors and their fossil-based counterparts. While both adhesive types exhibit robust adhesion properties and can function effectively even underwater, their performance diverges significantly upon exposure to strong oxidizing agents. The biobased adhesives demonstrate a remarkable reduction in stickiness—up to 99%—without undergoing significant changes in hydrophobicity, thanks to a unique blend of additional peptide functionalities.

In contrast, the fossil-derived adhesives experience only a 60% reduction in adhesion. This discrepancy can be attributed to their hydrophobic qualities, which although beneficial for adhesion, complicate the deactivation process due to the stability of the chemical structure involved. Börner cites that the multifunctionality inherent to biomaterials is what facilitates this efficient de-adhesion mechanism, enhancing the material’s operability in recycling and repair applications.

A Vision for the Future

As the research consortium continues its journey, the potential applications of these adhesives extend well beyond experimental triumphs. The future trajectory includes exploring the possibility of electrochemical oxidation methods, which could provide a more controllable and efficient means for deactivating adhesives. One promising application area is the repair of modern electronic devices—think smartphones, tablets, and computers—that are vital tools in our daily lives but often succumb to the fate of planned obsolescence.

The relevance of this research dwells not merely in the adhesive technology itself but in the broader implications for environmental sustainability. As the world grapples with e-waste and resource depletion, such innovations exemplify a conscientious shift toward a more sustainable paradigm. They embody a future where materials are not only functional but also compliant with the principles of a circular economy, aligning technology with ecological responsibility.

The integration of debondable adhesives into electronic manufacturing and repair could be a transformative step toward sustainable practices in the industry. This research underscores the synergy between nature and technology, proving that innovation rooted in biological principles can yield practical solutions to contemporary challenges. The journey toward a greener, more efficient technological landscape is underway, and adhesive innovation is at the forefront.

Leave a Reply