A groundbreaking study spearheaded by bioengineers at the University of California, Berkeley, has unveiled a pioneering adhesive polymer designed with environmental sustainability in mind. This innovative research, detailed in the journal Science, pivots on the clever use of an electrophilic stabilizer, which inhibits the depolymerization of a naturally occurring fatty acid, thus broadening its application as an effective adhesive. Such a development is particularly significant, given the increasing demand for non-harmful materials that can replace conventional, often toxic, adhesives in various sectors.

The Environmental Dilemma of Conventional Adhesives

Adhesives are integral to numerous industrial and medical applications, yet the majority are purpose-built for specific uses—such as woodworking—rendering them ineffective in other contexts. This scenario is compounded by the hazardous nature of many common adhesives, which pose risks to ecosystems and wildlife. Exploring alternatives, the UC Berkeley team sought to craft a polymer adhesive family that pivots away from traditional, petroleum-based compositions, addressing both functionality and environmental responsibility.

Leveraging Nature: The Role of Alpha-Lipoic Acid

The researchers focused on creating adhesives using alpha-lipoic acid (αLA), a fatty acid recognized for its natural biodegradability. This strategic choice not only reduces environmental impact but also leverages a resource that is abundant and eco-friendly. Their findings revealed that the application of an electrophilic stabilizer effectively preserved the integrity of the polymers, allowing for a versatile range of adhesives suitable for diverse uses, from mending tissues to bonding metals.

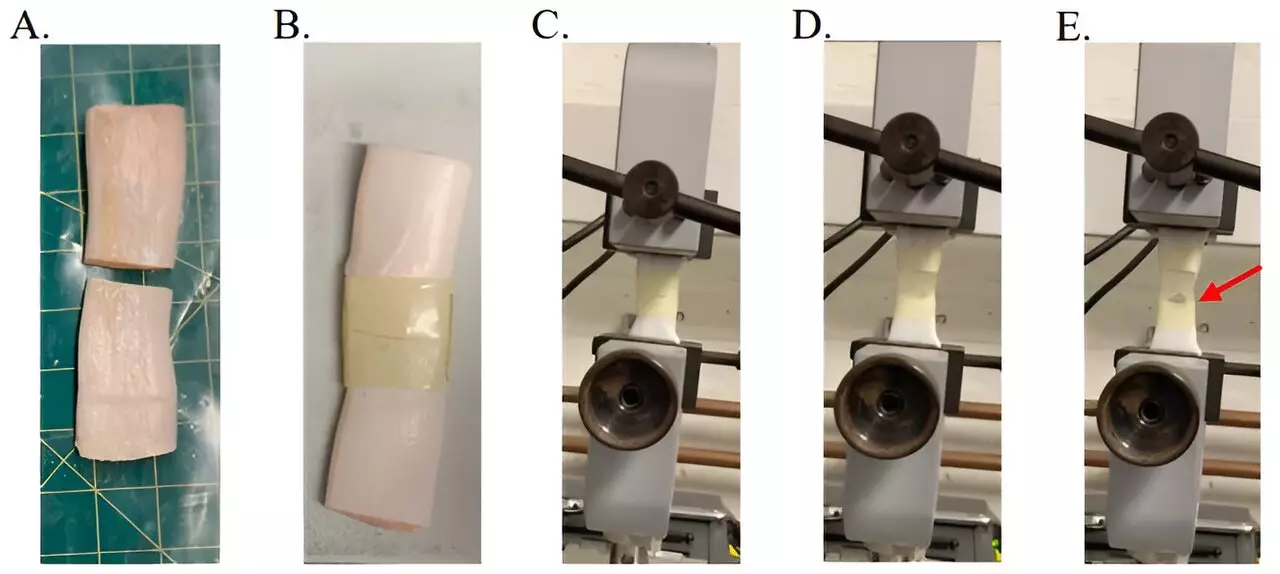

The study yielded remarkable results, demonstrating that these αLA-based adhesives exhibited substantial strength across various materials, including wood and metal. Notably, one variant of the pressure-sensitive adhesive showcased a peel strength tenfold greater than its conventional counterparts, ensuring durability in both wet and dry environments. Such characteristics elevate the potential of these adhesives for broader commercial and medical usage while underscoring their competitive edge against traditional options.

One of the standout features of this new adhesive family is its self-healing capability—a crucial aspect for applications in medicine where reliability is paramount. Patients and practitioners alike can benefit from materials that mend themselves upon minor damage, extending their lifespan and functionality. Furthermore, the research team proposed a novel closed-loop recycling system that allows for the transformation of used adhesives back into new products through simple techniques involving water. This innovation not only reduces waste but also reinforces the ethos of sustainability that underscores the entire project.

This innovative research from UC Berkeley represents a significant step forward in adhesive technology, offering environmentally friendly materials that come with the promise of safety and versatility. As industries globally seek to mitigate their ecological footprint, such developments will undoubtedly inspire further exploration into sustainable alternatives across the material science landscape. The future of adhesives, it seems, is not just strong and efficient but also kind to our planet.

Leave a Reply