Catalysts are fundamental to modern chemical processes, enabling the production of over 90% of the chemical materials we encounter daily. Their primary role is to facilitate and hasten chemical reactions, which often require less energy than non-catalyzed reactions. Without catalysts, many industrial processes would be inefficient or outright impossible. This necessity makes innovations in catalyst technology crucial for both economic and environmental sustainability.

Recent advancements from researchers at the Karlsruhe Institute of Technology (KIT) have introduced a promising approach to enhancing the performance of noble-metal catalysts. These precious metals, essential in various chemical reactions, are often expensive and scarce, leading to a growing demand for methods that minimize their use without compromising efficiency. The findings, published in the prestigious journal, Angewandte Chemie, underscore a significant leap forward in the quest for sustainable chemistry.

The team at KIT, led by Dr. Daria Gashnikova, has devised a methodology aimed at augmenting the stability of noble-metal catalysts while simultaneously reducing the quantity of these metals required for their creation. This project is particularly critical, given the environmental impact associated with mining and processing noble metals. By optimizing the structural configurations of catalysts, the researchers have produced active noble-metal clusters that maintain their efficiency, even when utilized in minimal quantities. This development marks a pivotal point for industries relying on noble metals, translating to both economic savings and an advancement towards resource sustainability.

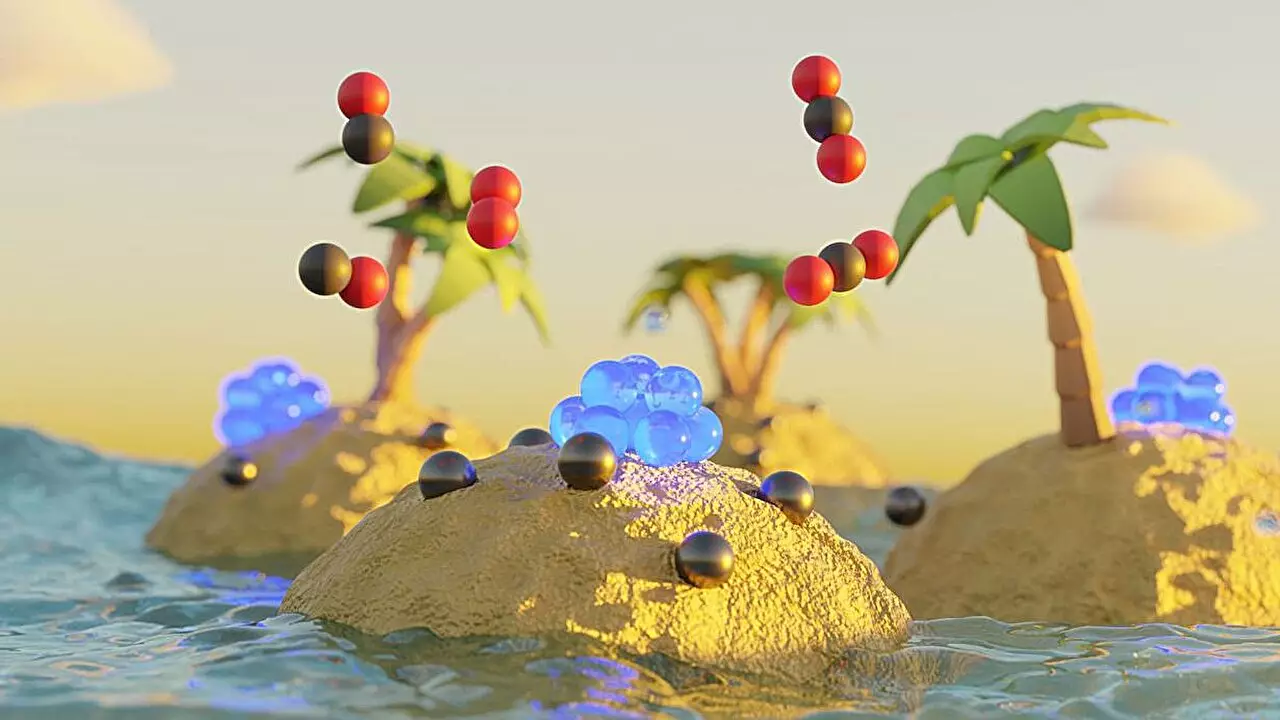

The research delves into the minute details of supported catalysts—where catalytic metals are distributed as tiny nanoparticles on a support substrate. This intricate setup can lead to fluctuating catalytic efficiency due to the dynamic nature of these clusters. Changeable structural interactions result in larger aggregates that diminish the number of available active sites on the catalyst, while fragmentation into isolated atoms can nullify the catalyst’s effectiveness. The KIT innovation addresses these issues by harnessing the unique interactions between noble metals and various support materials, effectively stabilizing these catalyst configurations.

The implications of this research extend far beyond academic interest. As industries face increasing pressure to operate sustainably, the reduction in noble metal usage without sacrificing performance represents a critical step forward. This innovation not only promises potential cost reductions for manufacturers but also aligns with global sustainability initiatives aimed at preserving our planet’s resources.

The work conducted at KIT is a remarkable stride in catalysis research that highlights the importance of innovation in chemical engineering. By exploring new ways to enhance catalyst stability and reduce resource consumption, researchers are paving the way for a more sustainable future in industrial chemistry, fundamentally transforming how we approach catalyst design and application.

Leave a Reply