The pressing nature of environmental issues has led scientists to continuously search for innovative materials that can effectively tackle challenges such as pollution and energy storage. Among these materials are covalent organic frameworks (COFs), unique structures that exhibit immense potential for applications ranging from gas capture to enhanced filtration. These crystalline polymers, characterized by their vast surface areas and customizable molecular structures, are proving to be essential tools in the quest for sustainable solutions. Their ability to trap gases and facilitate chemical reactions places them at the forefront of current environmental technologies.

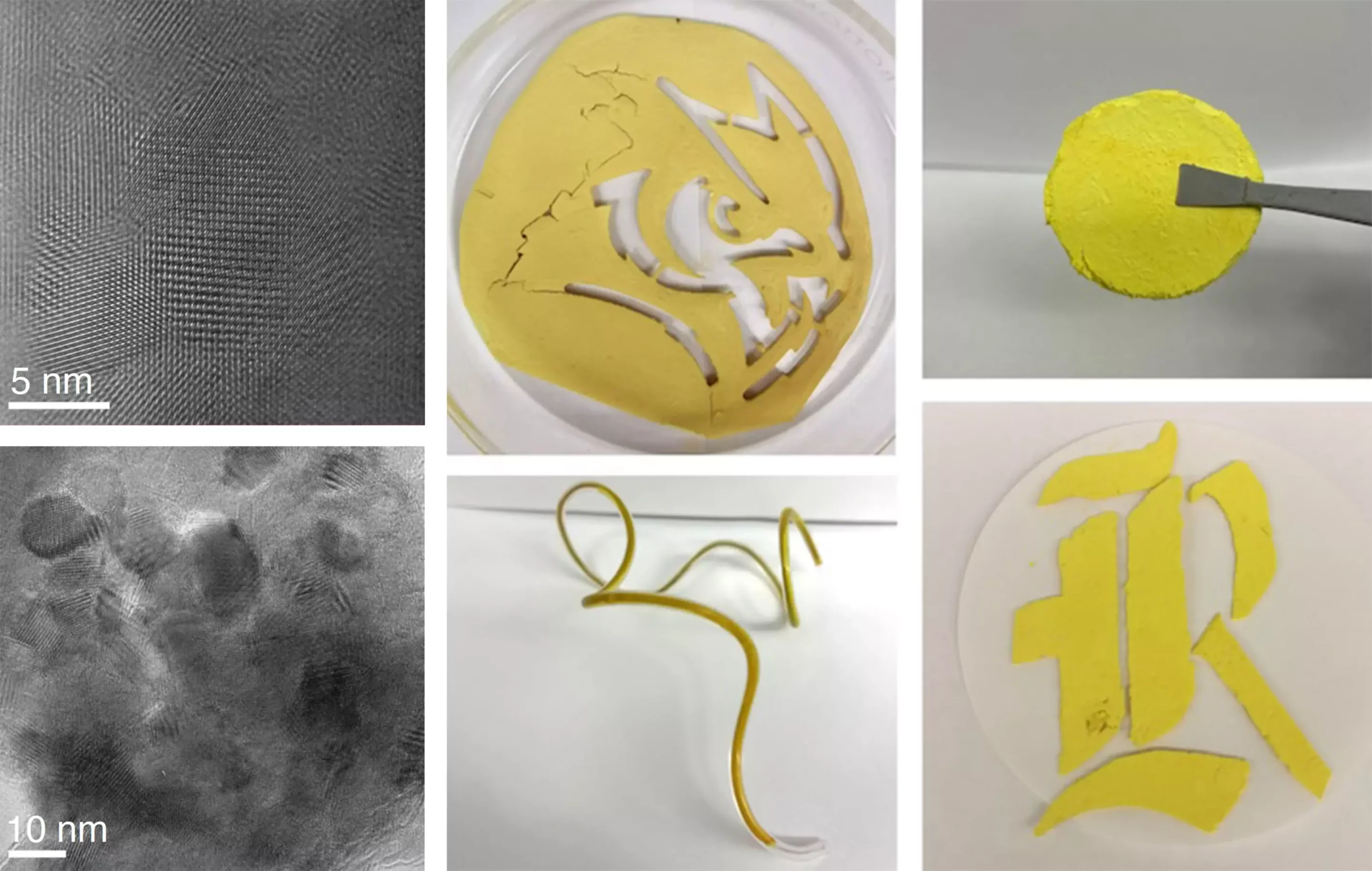

A noteworthy advancement in the production of COFs has emerged from the engineering team at Rice University, under the guidance of chemical engineer Rafael Verduzco. The latest research, published in ACS Applied Materials and Interfaces, unveils a novel synthesis technique that promises to enhance the quality of COFs while significantly reducing production costs and improving throughput. This study, which will be prominently featured on an upcoming journal cover, represents a critical step forward in the chemistry field and addresses the obstacles that have previously limited the widespread application of COFs.

One of the significant ramifications of this advancement lies in its potential to assist in detoxifying “forever chemicals”—specifically, per- and polyfluoroalkyl substances (PFAS)—which are notoriously resistant to breakdown in the environment. These harmful compounds are linked to a myriad of health issues, making the ability to efficiently degrade them crucial.

The Rice team has devised a continuous flow synthesis method, likened to operating a compact production line directly on a laboratory workbench. This innovative approach allows for the steady mixing and reaction of ingredients in a manner that differs fundamentally from traditional batch synthesis methods. “We built a small, continuous production system—like a minifactory on a lab bench—where the ingredients for COFs are mixed and reacted in a steady stream instead of all at once in a big container,” explained Safiya Khalil, a doctoral alumna involved in this project.

This new mechanism not only streamlines the production process but also promotes quality through precise control over mixing and temperature at every stage of synthesis. Notably, the researchers were able to demonstrate that one COF produced via this continuous method exhibited greater efficacy in decomposing perfluorooctanoic acid (PFOA) than its counterparts synthesized through traditional means. This finding underscores the tangible benefits of using modernized production techniques to enhance existing materials for environmental remediation.

Given the sustainability crises currently facing the planet, the implications of this research are profound. Khalil likened the new synthesis process to preparing cookies in small batches to ensure freshness and quality, instead of making a large batch at once. This analogy encapsulates the essence of the Rice researchers’ approach—prioritizing quality and efficiency to increase the availability of COFs, thereby facilitating the development of new formulations that could target specific environmental contaminants.

Beyond their applications in PFAS degradation, COFs are versatile materials that can theoretically be utilized across various domains, including pharmaceuticals, semiconductors, and advanced filtration technologies. The transition from a batch-processing model to a continuous flow system could lead to more accessible production methods, paving the way for industrial-scale applications that make use of COFs’ unique properties.

Impacts on Future Research and Applications

With the ongoing global emphasis on environmental sustainability, the meticulous research at Rice University stands as a potential game changer. By demonstrating that COFs can be synthesized in a more energy-efficient manner while still achieving superior material properties, this work not only lays the groundwork for future innovations in material science but also highlights a pathway toward resolving urgent environmental issues.

Moreover, the photocatalytic degradation process introduced alongside COF production further illustrates the potential for these materials to act effectively as “sunlight engines.” As Khalil eloquently described, envisioning COFs as sponges equipped with mechanisms to decompose harmful compounds under light activation offers a hopeful glimpse into how materials science can directly impact public health and environmental quality.

The pioneering work conducted by the Rice University team represents a significant stride in the synthesis and application of covalent organic frameworks. The transformation of COFs from niche materials into everyday solutions can be achieved through innovative methods that prioritize efficiency and sustainability. As research continues to evolve, the anticipation of COFs being integral in cleaner technologies and decontaminating processes presents an exciting frontier in the material sciences landscape, driving us closer to a healthier and much more sustainable planet.

Leave a Reply