Material science has often depended on conventional microscopy techniques that, despite their significance, have struggled to provide insights into the intricacies of atomic-level configurations within materials. A pivotal shift is underway as researchers from the University of Sydney unveil a compelling new microscopy method that circumvents previous limitations, promising to alter our understanding of crystalline materials. This innovation is not merely an incremental advancement; it represents a radical leap, allowing scientists to detect minuscule changes in atomic architecture with unprecedented clarity. The implications of this breakthrough extend from the aerospace sector to the electronics field, unlocking pathways to harness materials’ unique properties effectively.

Utilizing atom probe tomography (APT), the research team, guided by Professor Simon Ringer, delves into the architecture of materials on a fundamental level, often likened to deciphering a “materials genome.” This genomic perspective reveals the atomic relationships essential for the manifestation of material properties, thereby enhancing the potential for developing superior alloys and specialized semiconductors. By focusing on the short-range order (SRO)—the arrangement of atoms in close proximity—the researchers have opened a treasure trove of opportunities to craft materials that can meet the rigorous demands of modern engineering applications.

Understanding Short-Range Order: A New Dimension for Material Innovation

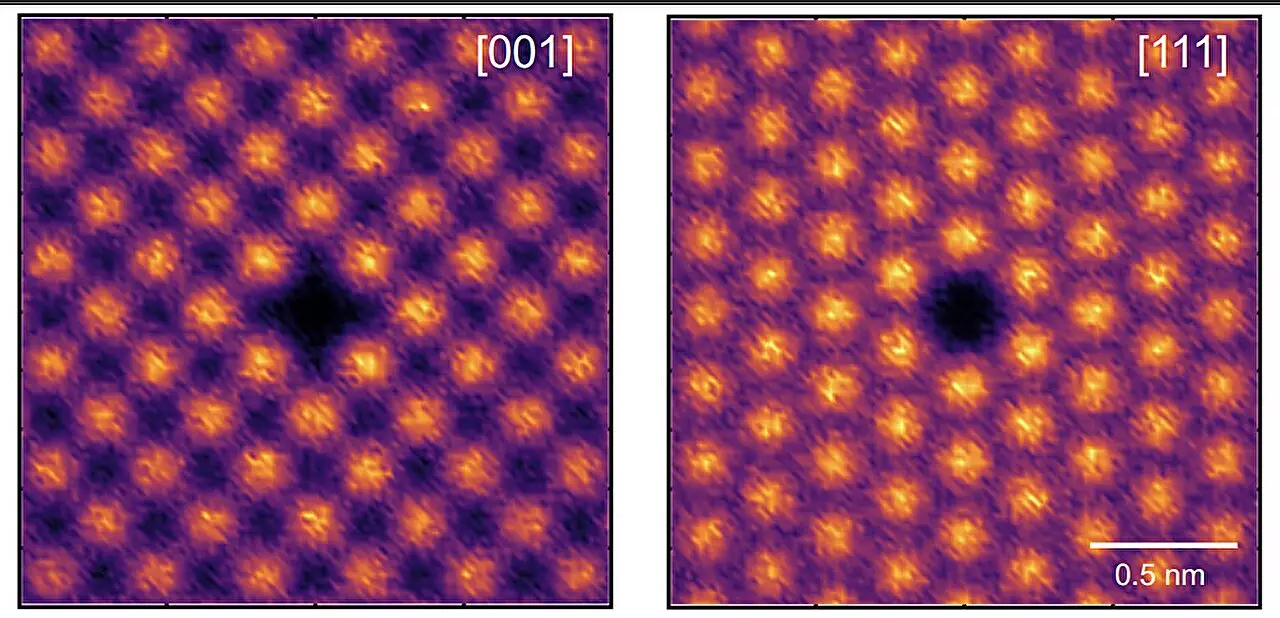

The concept of short-range order has historically eluded precise measurement, primarily due to the limitations of existing microscopy techniques. The challenge lies in the scale at which atomic arrangements occur, which is far beyond the reach of conventional methods. However, the new APT-driven approach transcends these barriers, granting researchers the ability to visualize and quantify SRO in ways that were previously unimaginable. This paradigm shift enhances our understanding of how the local atomic environment influences material properties such as strength, thermal resistance, and electrical conductivity.

Professor Ringer emphasizes that this new perspective allows scientists to go beyond mere structural symmetry and understand the nuanced neighborhood arrangements within crystals. Such insights are instrumental in formulating materials specifically designed for targeted applications, a concept that embodies the essence of personalization in material science. The implications of this technology are profound, particularly in high-performance industries such as aerospace and electronics, where material reliability and efficiency are paramount.

Applications in High Entropy Alloys and Beyond

As the study concentrates on high entropy alloys (HEAs), its relevance to cutting-edge engineering practices becomes even more pronounced. HEAs have garnered global attention for their potential applications in high-temperature environments such as jet engines and power plants. Beyond that, their role as radiation shields in nuclear reactors signifies their critical importance in industries necessitating durability and safety. The potential to create enhanced versions of these alloys, tailored atom-by-atom to achieve specific properties, is nothing short of revolutionary.

Moreover, the research team employed advanced data science techniques to extract and analyze valuable information from APT data, allowing for a deeper understanding of how SRO evolves under varying conditions. For instance, observations of a cobalt-chromium-nickel HEA revealed that different heat treatments can significantly alter its SRO. This knowledge not only serves as a foundational template for future studies but also positions researchers to manipulate material properties in manners that align with specific engineering needs.

A Deeper Look at the Future of Materials Science

The implications of this groundbreaking research extend to modeling and simulation as well, offering material scientists a detailed atomic-scale blueprint from which to work. Dr. Andrew Breen’s commentary highlights a shift in the paradigm, where SRO not only enriches the experimental approaches but also anchors computational models that predict material behavior. This capacity to simulate material response under varying conditions can propel design strategies to new heights, enabling the creation of materials that are not only tailored for performance but also sustainable and cost-effective.

As the academic community discusses and explores the ramifications of these findings, professionals like Dr. Will Davids envision practical benefits for the wider materials science and engineering cohort. The ability to measure SRO in multicomponent alloys opens up unchartered territories for innovative design, potentially leading to a new wave of materials that meet evolving industrial needs.

In sum, the revelations from this study encapsulate a transformative moment in material science. By unlocking the atomic-level intricacies that dictate material performance, researchers are not just enhancing existing knowledge but pioneering a future in which materials can be custom-designed to optimize functionality. This paradigm shift could revolutionize industries reliant on advanced materials, transforming engineering from a field of reactive adaptations to one of proactive, custom-tailored innovation.

Leave a Reply