The tradition of manipulating materials dates back to ancient civilizations, where craftsmen discovered that the act of deforming metals could lead to increased strength. This crucial insight gave rise to the art of blacksmithing during the Bronze and Iron Ages. As these early artisans bent and hammered metals, they unintentionally stumbled upon what is now understood as “work hardening,” a process by which metals become stronger when subjected to mechanical stress. Fast forward to contemporary times, this principle remains foundational in metallurgy, influencing a variety of applications from automotive engineering to electrical grid construction. Yet, despite the longstanding importance of work hardening, the intricate processes operating at the atomic level had eluded direct observation—until recently.

Breakthrough Research at Harvard

In a groundbreaking study led by a team at the Harvard John A. Paulson School of Engineering and Applied Sciences, researchers successfully observed work hardening in real-time. This significant advancement, reported in the journal *Nature*, offers critical insights into the mechanisms that dictate material strength. The study is particularly groundbreaking, not just for its findings but for the new methodologies adopted to explore an area of material science that has long been shrouded in mystery. As Frans Spaepen, a leading figure in the study, pointed out, a deeper understanding of the laws governing work hardening can profoundly affect material design and manufacturing techniques.

The complexities surrounding work hardening often stem from the atomic structures known as dislocations—defects within a material’s crystalline lattice that play a pivotal role in how it hardens when deformed. Traditionally, researchers have utilized electron microscopy to compare the structures before and after deformation, limiting our understanding of the dynamic interplay occurring during the hardening process. This limitation spurred the Harvard team to innovate an approach that transcends conventional observations.

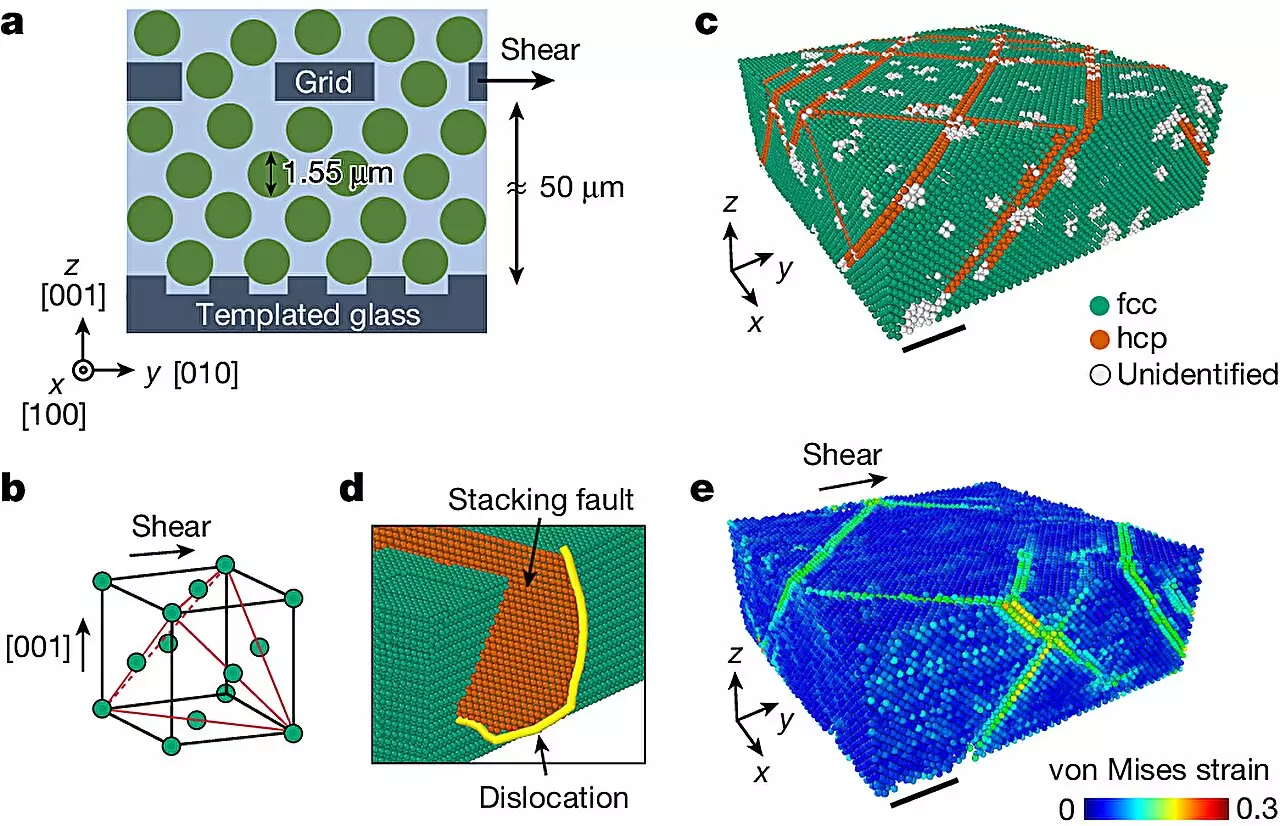

To unlock the secrets of work hardening, the research team turned to colloidal crystals—structures that form from large particles that are approximately 10,000 times bigger than atoms. These larger particles create appealing analogs for atomic systems because they exhibit similar structural and phase behavior, including the formation of dislocations. Despite their relatively soft nature—reportedly over 100,000 times softer than Jell-O—colloidal crystals provide a unique platform for observing the hardening process in greater detail.

Employing advanced imaging through a confocal optical microscope, researchers subjected these colloidal crystal particles to strain. They meticulously tracked the patterns of movement among particles in real time, revealing surprising findings: these ultra-soft materials displayed remarkable work hardening—outperforming even many well-known metals like copper and aluminum. This unexpected outcome challenges existing perceptions about the relationship between material softness and strength.

A Paradigm Shift in Understanding Material Strength

The implications of this research extend far beyond the study of colloidal crystals. By demonstrating that work hardening is dictated largely by the geometric configurations and interactions of the particles, the study provides universal insights relevant to a variety of materials. The interaction and entanglement of dislocation defects within these soft materials resulted in a surprising increase in strength—a revelation that transforms our understanding of material properties.

David A. Weitz, another eminent researcher involved in the study, emphasized the fundamental and universal nature of the findings: soft materials can indeed possess extraordinary strength due to work hardening. This revelation opens new avenues for materials scientists and engineers as they rethink how they create and utilize materials in diverse applications. It suggests that even materials conventionally deemed inadequately robust can be enhanced through specific structuring and processing techniques, leading to innovations in manufacturing and design.

As this research illuminates the mechanisms of work hardening, it presents a pivotal moment in material science. The insights gained in observing colloidal crystals in real time could inform the development of new materials with tailored properties, optimizing strength while maintaining desirable soft characteristics. The potential applications of this knowledge are vast, impacting everything from construction materials to biomedical devices.

In the grand tapestry of science, this study serves as a reminder of the surprising intricacies underlying seemingly simple processes. As researchers continue to deepen their understanding of the relationships between structure and strength, the possibilities for engineering advanced materials are limited only by our creativity and ambition. The journey through the world of materials science has just taken an exciting turn, promising it will lead to richer innovations and enhanced capabilities in the years to come.

Leave a Reply