In the midst of summer’s sweltering embrace, the need for innovative solutions to combat heat becomes apparent. Whether one is an athlete, a casual park-goer, or a dedicated landscaper, the discomfort from excessive heat can be a deterrent to outdoor activities. Traditionally, textiles that reflect sunlight or promote heat dissipation have relied heavily on specialized fibers or sophisticated manufacturing techniques. However, recent advancements led by researchers from the University of Massachusetts Amherst have paved the way for an effective cooling fabric using a surprisingly simple and economically sustainable approach.

At the forefront of this groundbreaking development is Evan D. Patamia, a graduate student engaged in a collaborative project that aims to redefine outdoor comfort. Their innovative discovery involves a chalk-based coating capable of lowering air temperatures beneath treated fabric by as much as 8 degrees Fahrenheit. This revelation will be shared at the American Chemical Society’s fall meeting, a prominent scientific gathering featuring around 10,000 presentations spanning various domains of research.

Trisha L. Andrew, a chemist and materials scientist collaborating closely with Patamia, highlights the fundamental problem that the team sought to address. The combination of ultraviolet (UV) and near-infrared (near-IR) light from the sun, when absorbed by both skin and clothing, contributes to rising temperatures. As our bodies generate heat through metabolic processes, effective materials are essential to minimize discomfort when venturing outside.

To tackle this issue, researchers have been developing textiles engineered to reflect sunlight while simultaneously allowing the natural heat from the body to escape—a process referred to as radiative cooling. Previous materials often incorporated synthetic particles like titanium dioxide or aluminum oxide, or utilized organic polymers reliant on toxic PFAS compounds, known colloquially as “forever chemicals.” Such materials came with a hefty environmental price tag, leading Andrew to challenge her team to seek out more eco-friendly alternatives.

Inspired by historical cooling practices that employed crushed limestone-based plasters, the researchers identified calcium carbonate as an optimal material to serve their purpose. Combined with bio-compatible barium sulfate, this natural composition offers a sustainable option without compromising performance. The innovative application method utilizes chemical vapor deposition (CVD), a technique that merges the processes of synthesis and deposition into a streamlined application. This approach not only minimizes ecological impact but also enhances the durability of the fabrics.

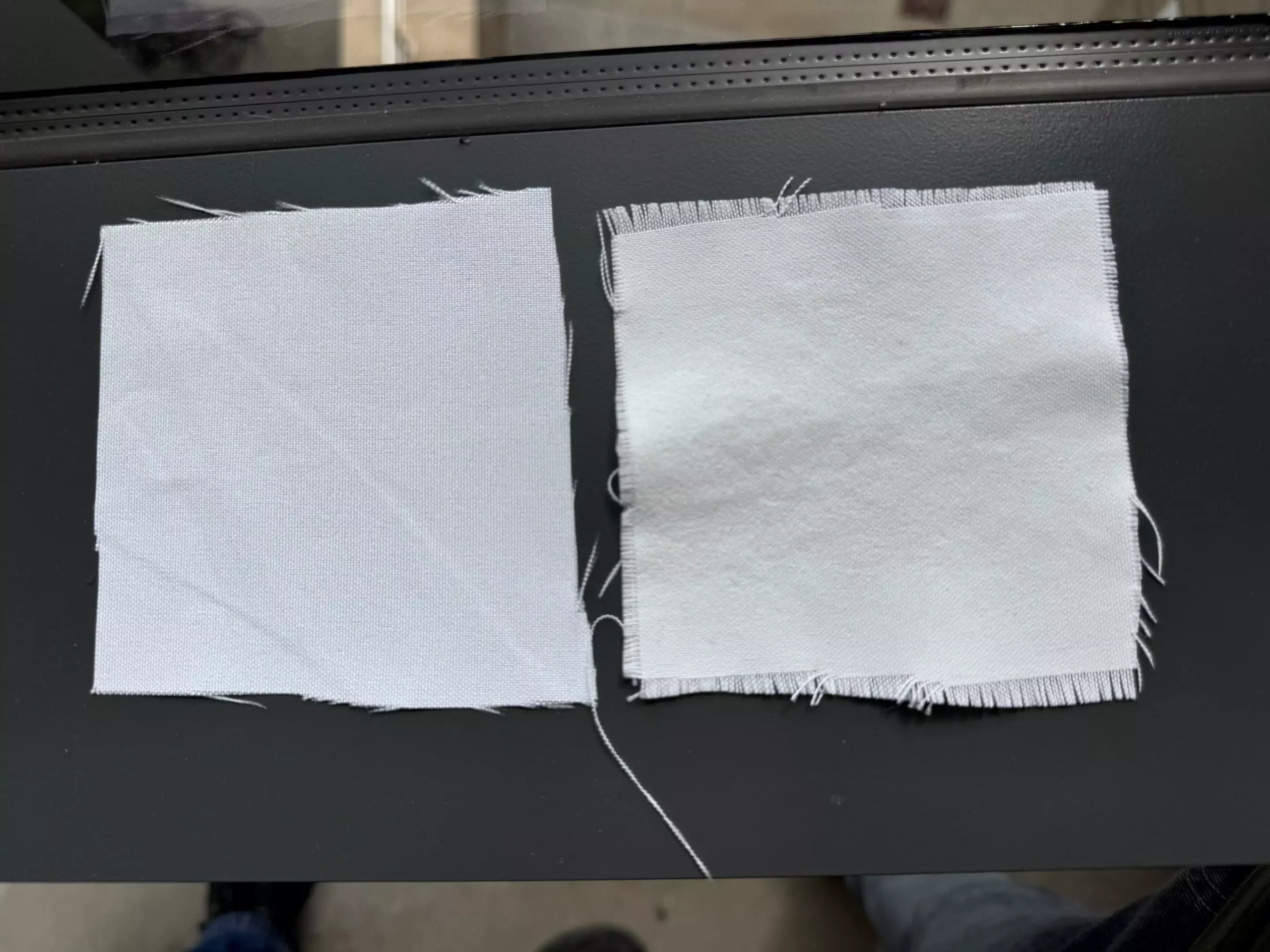

To develop this fabric treatment, Patamia and fellow researcher Megan K. Yee executed a meticulous method involving layering a thin polymer coating onto fabric followed by repeated immersion in solutions containing calcium and barium ions. This technique allows for customized manipulation of crystal size to achieve optimal functionality in light reflection. With these enhancements, the resulting fabric boasts a chalky and matte finish effective at reflecting harmful UV and near-IR light.

Field tests conducted on sunny days demonstrated the efficacy of the newly treated fabrics, elucidating a cooling effect that could significantly enhance outdoor comfort. Remarkably, the temperature measured under the treated fabric recorded an astonishing 8 degrees Fahrenheit lower than the surrounding atmosphere, and in certain instances, the difference soared to 15 degrees. Such results not only underscore the practicality of this new textile but also its potential to revolutionize outdoor recreation and work environments during the hottest months of the year.

A crucial aspect of textile innovation is durability, especially concerning exposure to regular laundering. In testing the physical resilience of the mineral-polymer coating against the rigors of washing, Yee found that the cooling properties remained intact post-laundry, indicating longevity in real-world applications.

Moving forward, Andrew’s aspirations for the commercial viability of this invention include scaling up the CVD process to accommodate larger fabric dimensions. Initiatives to launch a startup aim to transition lab-scale innovations into broader market-ready solutions, presenting new opportunities for fabric that incorporates this revolutionary cooling technology across multiple platforms.

The collaboration among Andrew, Patamia, and Yee signifies a pivotal moment in the convergence of sustainability and cutting-edge material science. The introduction of chalk-based cooling fabrics embodies an ecological approach to textile manufacturing while greatly enhancing comfort in extreme temperatures. With no reliance on external power sources, this invention summarizes a promising direction for future fabric developments, ideally suited for communities combating heat stress in challenging environmental conditions. As the importance of climate-conscious and consumer-friendly innovations grows, these researchers are contributing crucial advancements that could redefine how we engage with the summer sun.

Leave a Reply