Engineers at the University of California, San Diego, have embarked on a transformative journey in the realm of materials manufacturing through a pioneering 3D printing method. Their innovative technique utilizes a polymer ink combined with a saline solution, leading to the creation of solid structures in an unprecedented manner. This advancement, highlighted in their publication in *Nature Communications*, promises a significant reduction in the environmental impact associated with traditional manufacturing processes.

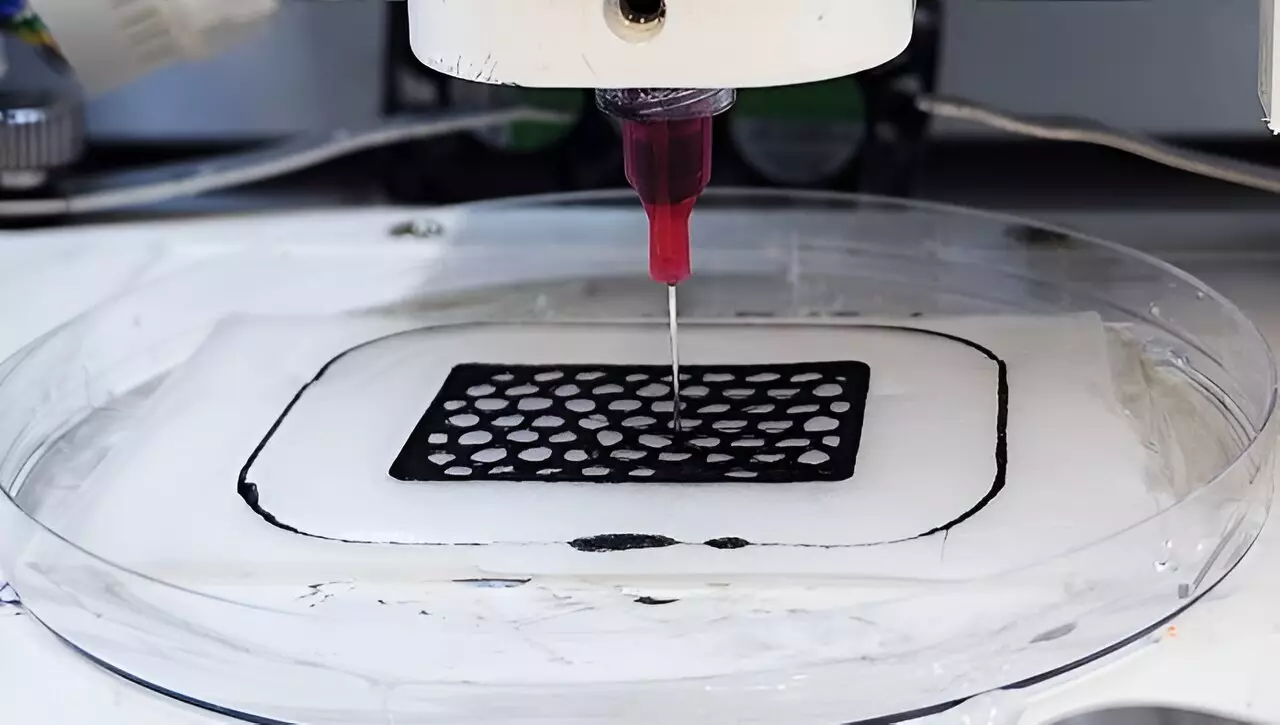

At the core of this novel technique is poly(N-isopropylacrylamide), commonly referred to as PNIPAM. When this polymer ink is extruded into a solution of calcium chloride, it undergoes immediate solidification upon contact with the saline environment. This quick transition from liquid to solid state is a result of the salting-out effect, where the presence of salt ions actively draws water away from the polymer. The synergistic interaction between the hydrophilic nature of water and the hydrophobic properties of the polymer leads to a rapid aggregation of polymer chains, thus creating a solid structure.

What sets this technique apart from traditional polymer solidification methods is its reliance on ambient conditions, eliminating the necessity for energy-intensive processes, harsh chemicals, and extreme temperatures. Senior author Jinhye Bae emphasizes that their approach not only simplifies the manufacturing process but also prioritizes environmental sustainability. By harnessing the natural interaction between PNIPAM and salt water, the method avoids the ecological toll of conventional techniques, thereby paving the way for greener manufacturing practices.

Another remarkable aspect of this new 3D printing process is the reversibility it offers. The solid structures created can easily dissolve in fresh water, allowing for the repurposing of the PNIPAM ink for future uses. This characteristic introduces a sustainable lifecycle for polymer materials, as indicated by Bae’s assertion that the method provides a straightforward solution for recycling.

The versatility of this method has been further demonstrated by the researchers, who successfully printed a functional electrical circuit using PNIPAM mixed with carbon nanotubes. This circuit was capable of powering a bulb, showcasing the potential for creating not just structural components, but also recyclable electronic elements. The ability to dissolve these circuit components in water adds an exciting dimension to the field of electronics manufacturing, aligning with the growing global demand for sustainable technology solutions.

The future of polymer manufacturing is being reshaped by this innovative 3D printing technique. By addressing both the ecological challenges posed by traditional methods and the need for sustainable recycling processes, researchers at UC San Diego are charting a course toward a cleaner, more efficient future for material production. As they continue to refine their techniques and explore new applications, the impact of their work could resonate well beyond the confines of academic research, influencing industries worldwide to adopt environmentally friendly practices.

Leave a Reply