Recent advancements in concrete science have set the stage for a paradigm shift in the design and application of ultra-high-performance concrete (UHPC), particularly in combination with fiber-reinforced polymers (FRP). A meticulous study spearheaded by S.S. Zhang, J.J. Wang, Guan Lin, and X.F. Nie has introduced an innovative stress-strain model that addresses the unique challenges associated with FRP confinement. By focusing on the compressive behavior of FRP-confined UHPC, this research promises to fill significant gaps in contemporary structural engineering paradigms, ultimately enhancing the performance and safety of UHPC structures.

Ultra-high-performance concrete has emerged as a material of choice in modern construction due to its unparalleled strength, durability, and ability to withstand challenging environmental conditions. Unlike traditional concrete, UHPC exhibits properties that can significantly enhance the longevity and resilience of structures. However, the complexities involved in predicting how UHPC performs under confinement from FRP have long posed a challenge for engineers. Traditional stress-strain models that have served well for normal-strength concrete (NSC) fail to capture the nuances of UHPC behavior, creating a pressing need for deeper exploration and understanding.

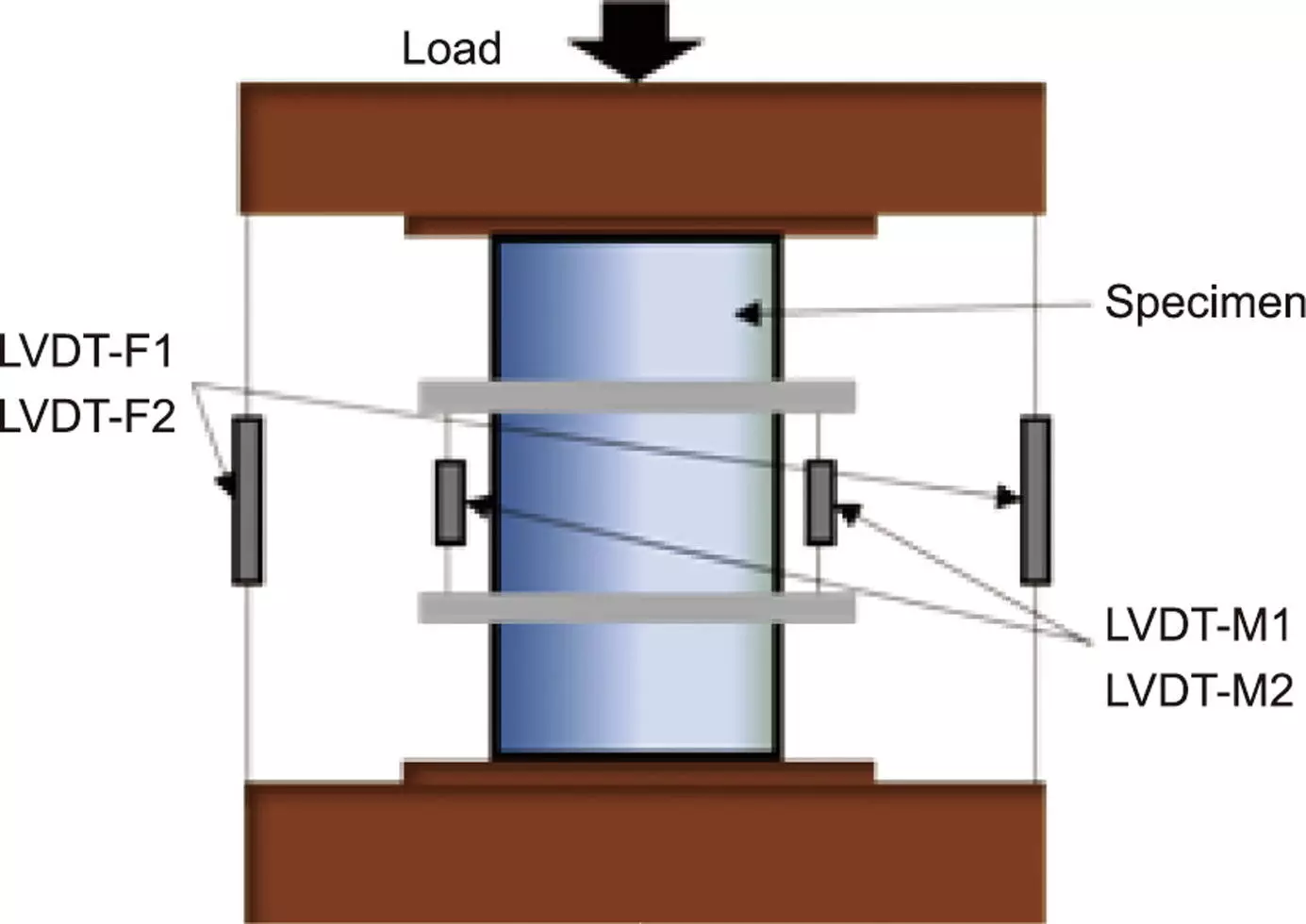

The research conducted by the team from Huazhong University of Science and Technology and Southern University of Science and Technology revealed critical insights into the failure mechanisms of UHPC under concentric compression. By systematically examining the response of UHPC confined by FRP, they uncovered that existing assumptions, such as the widely accepted stress-path-independency principle, do not adequately apply. The study highlighted that while these models work effectively for NSC, the behavior of UHPC diverged significantly, necessitating a reevaluation of conventional frameworks.

One notable discovery was the occurrence of major diagonal cracking within the FRP-confined UHPC. This phenomenon led to non-uniform lateral expansion, which subsequently decreased the confining pressure exerted by the FRP on the UHPC. Such findings prompted the researchers to rethink the applicability of stress-path-independency and acknowledge the complexities unique to UHPC.

In response to these findings, the researchers formulated a new analysis-oriented stress-strain model that incorporates stress-path dependency, fundamentally altering the approach to FRP-confinement design. By adjusting existing equations and integrating a new parameter to represent the confining pressure gap between the FRP and the UHPC, the model reflects a more accurate representation of UHPC behavior under confinement.

This progressive model underwent extensive testing against a comprehensive database of experimental data, showcasing its ability to predict the stress-strain behavior of FRP-confined UHPC with remarkable precision. The validation results confirmed the model’s superiority over traditional methods, establishing it as a more reliable tool for engineers tasked with the design and analysis of UHPC-integrated structures.

The findings from this study have far-reaching implications for the construction sector. By providing engineers with a more complete and accurate understanding of UHPC behavior under FRP intervention, the potential for innovative structural designs increases markedly. The adoption of the new model can optimize design processes, ensuring that structures are not only safe but also efficient in their use of materials.

Moreover, as the construction industry gravitates toward high-performance materials, the insights gained from this research pave the way for future investigations into concrete technology. Enhanced predictive capabilities can lead to smarter, more sustainable construction methods that prioritize safety and durability while minimizing waste.

The innovative research on FRP-confined UHPC represents a significant leap forward in the field of structural engineering. By challenging existing paradigms and providing a refined analytical approach, the findings enable more effective design and engineering practices. As the industry embraces the findings of this study, it paves the way for advancements that could redefine how high-performance concrete is utilized in diverse structural applications, setting a new standard for the future of concrete technology and construction safety.

Leave a Reply