An innovative research team at the Korea Institute of Materials Science, spearheaded by Dr. Sung Mook Choi, has made significant strides in electrode fabrication for anion exchange membrane water electrolysis. Their groundbreaking work introduces a one-step electrode fabrication process, a first for South Korea, which streamlines the production of electrodes directly from raw materials to a mass-producible level.

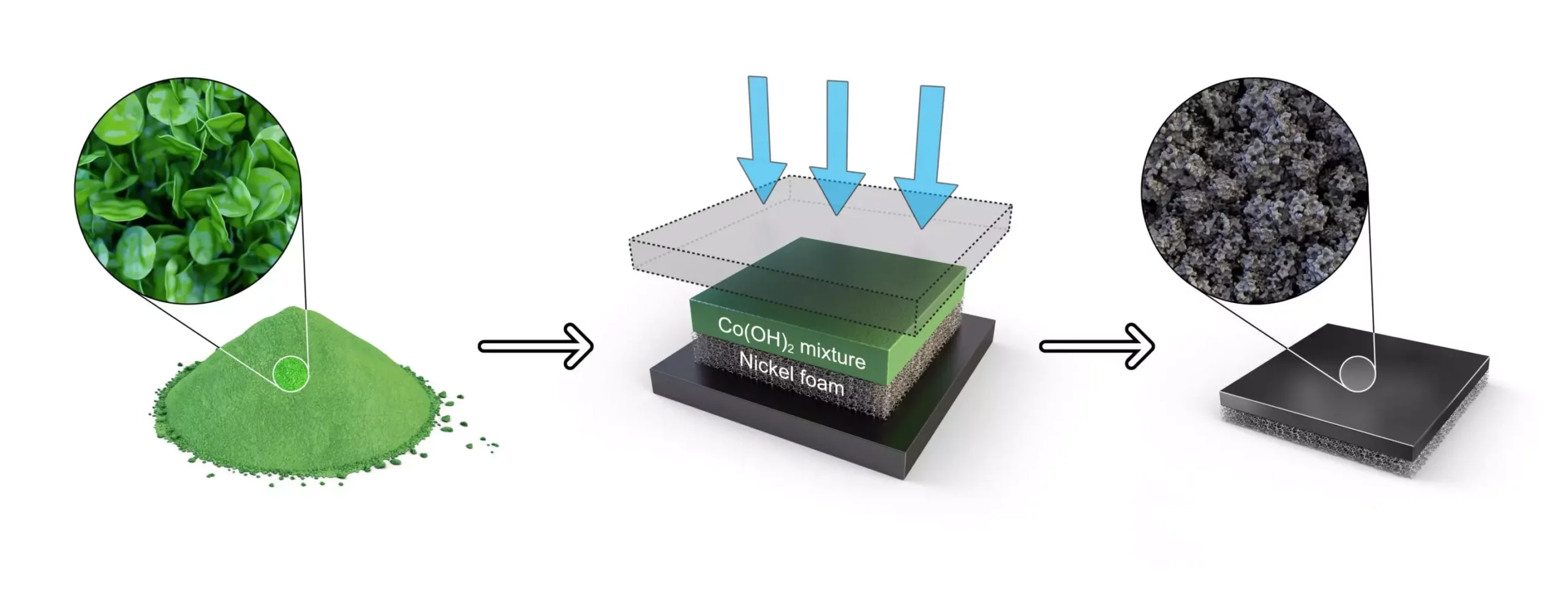

The team’s research, recently published in the journal Applied Energy, showcases the implementation of this new process on a commercial-scale stack of anion exchange membrane water electrolyzer. By utilizing a one-step hot-pressing process, cobalt hydroxide is converted into a cobalt oxide catalyst, while simultaneously forming a highly uniform catalyst layer. This advancement replaces the intricate steps of the traditional process with a single coating step, simplifying the process by 60% and ensuring the creation of a uniform catalyst layer. Furthermore, the efficiency of hydrogen production and the durability during continuous operation have shown significant improvements with this new electrode fabrication process.

In order to optimize the one-step electrode fabrication process, the research team meticulously controlled the cobalt hydroxide slurry conditions, as well as the temperature and pressure during the hot-pressing process. This led to the successful fabrication of a catalyst layer composed of uniform oxide particles, each measuring 10 nanometers in size. The developed electrode was further utilized to create a membrane electrode assembly (MEA) incorporating an anion exchange membrane and a hydrogen evolution catalyst, confirming its stability and performance in a commercial-scale water electrolysis cell.

Future Prospects in Green Hydrogen Production

The potential for green hydrogen production from water electrolysis is immense, with projections reaching 11 million tons and 69 gigawatts of capacity by 2030. In Korea, efforts are underway to develop technology for a megawatt-level anion exchange membrane water electrolysis system by 2024, with hopes of commercializing it by 2030. Although the current domestic level of anion exchange membrane water electrolysis technology stands at approximately 70-80% of the world-class standards, significant investment and technology localization are crucial to further advancement in this field.

Securing Global Leadership

Through the development of this advanced electrode fabrication process, the research team aims to secure a global edge in related technologies, localize water electrolysis technology, and dominate overseas water electrolysis markets. Dr. Sung Mook Choi, the principal researcher, emphasized the significance of this achievement in addressing key challenges related to the commercialization of anion exchange membrane water electrolysis.

The innovative one-step electrode fabrication process developed by the research team at the Korea Institute of Materials Science represents a significant milestone in the field of anion exchange membrane water electrolysis. Its efficiency improvements, durability enhancements, and potential for global leadership in the industry highlight the importance of continued research and development in sustainable hydrogen production technologies.

Leave a Reply