Imagine a world where your milk carton could communicate with your smart phone to let you know when it has gone bad, all thanks to printed electronics. This innovative technology, consisting of thin and flexible electronic circuits, has the potential to revolutionize the way we interact with everyday objects. From solar cells on vehicle roofs to flexible displays on smartphones, printed electronics are already making waves in the tech industry.

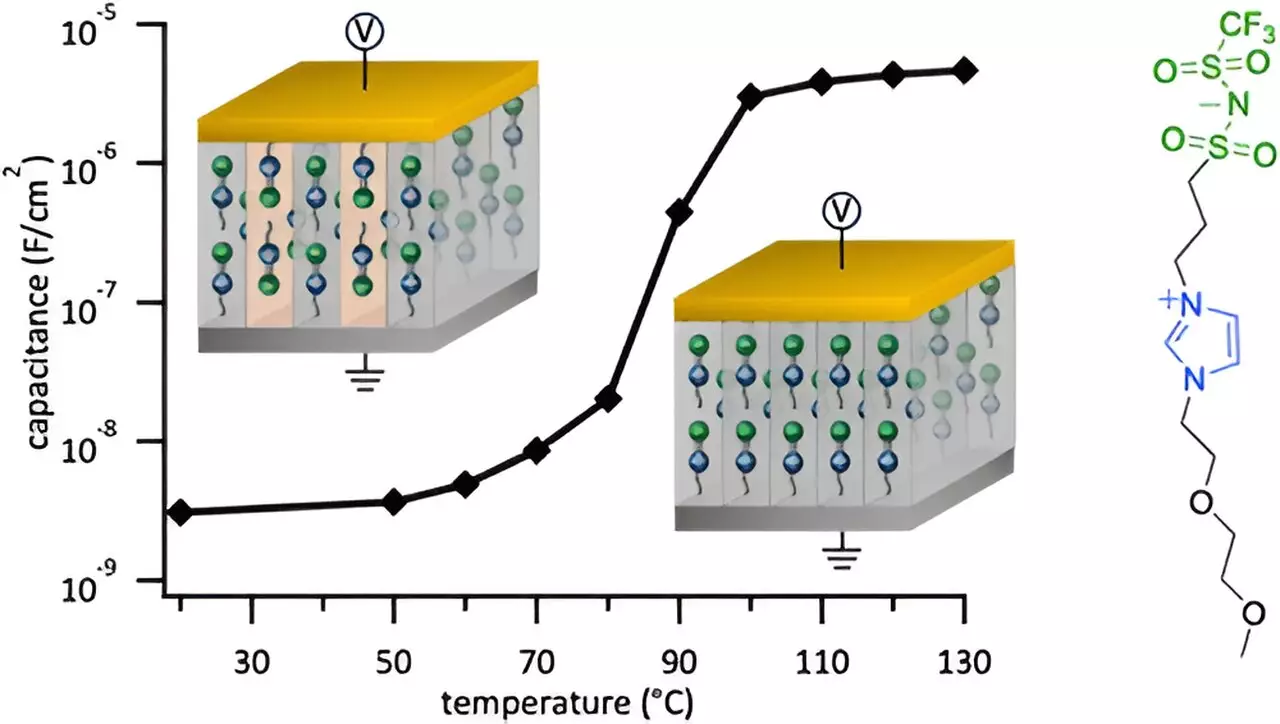

A recent breakthrough in material development, achieved by a team of researchers from Simon Fraser University (SFU) and the University of Saskatchewan (USask) using the Canadian Light Source (CLS), has resulted in a material that stores up to 1,000 times more charge than current forms of printed electronics. This advancement brings us one step closer to realizing the concept of the Internet of Things, where everyday objects are equipped with electronic capabilities to enhance connectivity with our devices.

The integration of printed electronics into common household items such as milk cartons and refrigerators has the potential to have a profound impact on various industries, particularly the food industry. By minimizing waste and spoilage at all levels of the supply chain, printed electronics can improve efficiency and reduce costs. This technology opens up a realm of possibilities for enhancing communication between objects, devices, and users.

For the Internet of Things to become a reality, advanced circuitry that can operate in both positive and negative voltage modes is essential. The material developed by Loren Kaake and his team at SFU’s Department of Chemistry demonstrates promise in this area, outperforming even the most cutting-edge materials currently available. This breakthrough paves the way for the commercial potential of printed electronics, driving innovation and technological advancement.

The team utilized the intense synchrotron light at the CLS to analyze and enhance the performance of their material, gaining insights into its nanoscale structure. By understanding what factors contribute to optimal performance and what hinders it, the researchers have laid the groundwork for further material engineering. Their findings, published in the journal ACS Applied Materials and Interfaces, provide valuable information for the advancement of printed electronics.

Kaake predicts that printed electronics will enter the marketplace within approximately seven years, bringing with it a new era of technological integration. As prototypes are developed, the advanced material can be readily implemented, accelerating the adoption of printed electronics in various applications. The ongoing research and development of new materials are crucial for driving innovation and meeting the evolving needs of the tech industry.

Leave a Reply