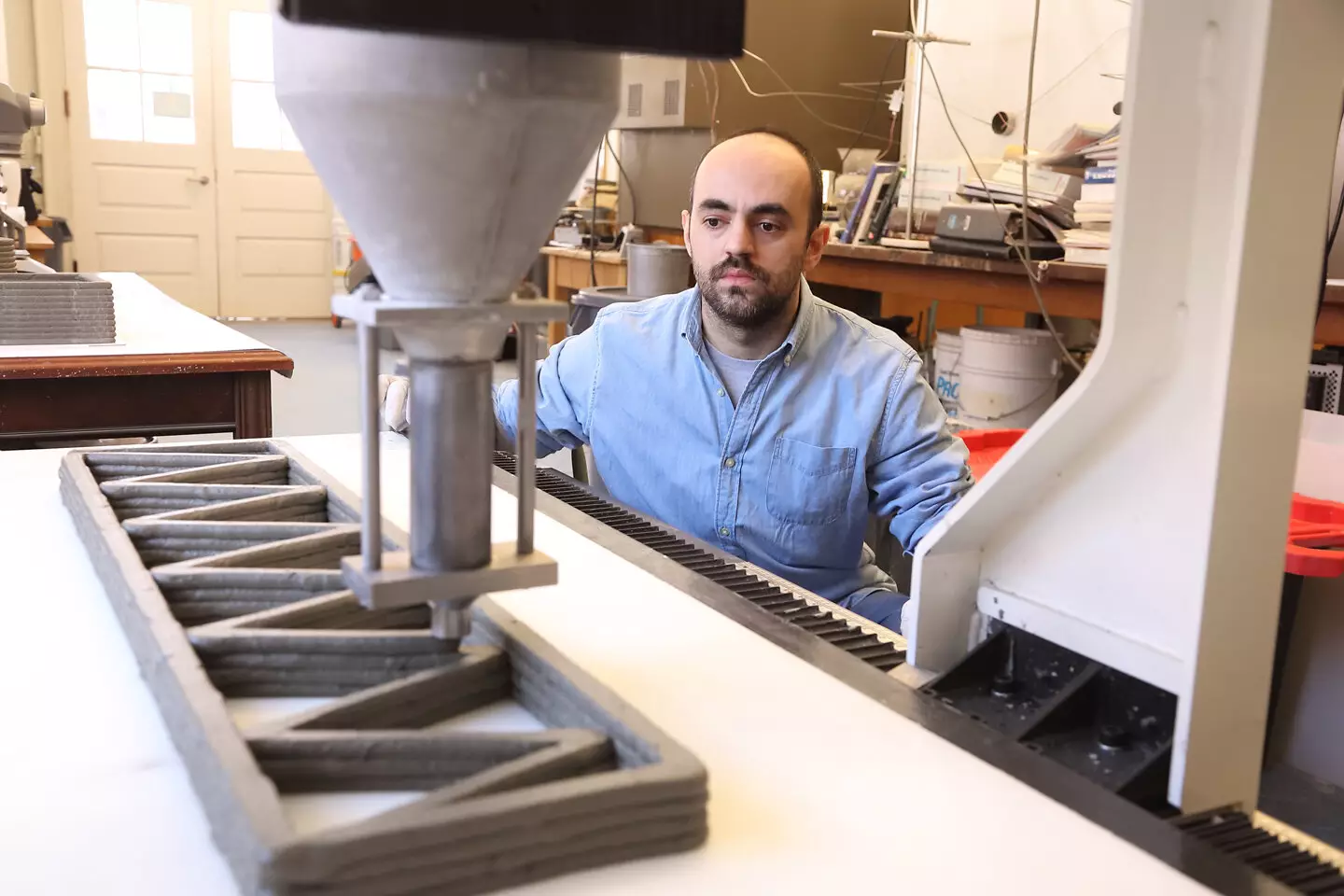

In a groundbreaking study conducted by engineers at the University of Virginia School of Engineering and Applied Science, the potential benefits of incorporating cellulose nanofibrils (CNF) into 3D-printed concrete technology were explored for the first time. The findings of this research hold significant promise for the advancement of sustainable and resilient construction practices in the near future.

Despite the numerous advantages of 3D-printed concrete, such as quick construction, reduced labor costs, and intricate designs, existing printable material options are limited, and concerns about their sustainability and durability persist. The challenge lies in achieving a balance between the flow properties required for smooth fabrication and the critical mechanical strength needed for structural integrity and thermal conductivity.

Cellulose nanofibrils, derived from wood pulp, offer a renewable and low-impact alternative for enhancing the rheology and mechanical strength of composites. Commonly referred to as CNF in the industry, this plant-based material has shown strong potential as an additive to improve the performance of 3D-printed concrete structures. However, prior to the research conducted by the UVA team, the specific influence of CNF on conventional 3D-printed composites remained unclear.

Through meticulous experimentation with varying quantities of CNF additive, the research team observed a significant improvement in flow performance with as little as 0.3% CNF. Microscopic analysis of hardened samples revealed enhanced material bonding and structural integrity, indicating the potential for increased durability. In subsequent tests involving pulling, bending, and compression, CNF-enhanced 3D-printed components demonstrated superior mechanical properties compared to conventional materials.

The implications of this research extend beyond the realm of construction, offering a glimpse into the transformative potential of sustainable materials in advancing infrastructure development. By harnessing the unique properties of cellulose nanofibrils, engineers can pave the way for eco-friendly and resilient construction practices that address the growing challenges of urbanization and environmental sustainability.

The integration of cellulose nanofibrils into 3D-printed concrete technology represents a significant step towards redefining the future of construction. By leveraging the inherent benefits of plant-based materials, researchers and engineers have the opportunity to revolutionize the way we build and design infrastructure, paving the way for a more sustainable and resilient built environment.

Leave a Reply