In today’s rapidly evolving technological landscape, the materials we utilize play an indispensable role, especially in sectors that demand resilience under extreme conditions. Industries such as aerospace, nuclear energy, and military applications require materials that can endure significant pressure, high temperatures, and corrosive environments. To pave the way for innovations in these fields, it is imperative to study the microscopic behavior of materials under these demanding scenarios. This exploration not only aids in enhancing the performance of existing materials but also lays the foundation for the development of smarter, more sustainable alternatives.

Recent research led by scientists at the Lawrence Livermore National Laboratory (LLNL) has focused on the behavior of zirconium—an elemental metal renowned for its strength and low neutron absorption properties. In their groundbreaking study, the team compressed single crystal samples of zirconium, revealing that under high-pressure conditions, the deformation patterns of the material were more complex than previously recognized. Unlike standard observations that often depict a straightforward response to stress, the zirconium samples exhibited a multitude of deformation mechanisms, prompting a reassessment of existing models detailing material behavior under pressure.

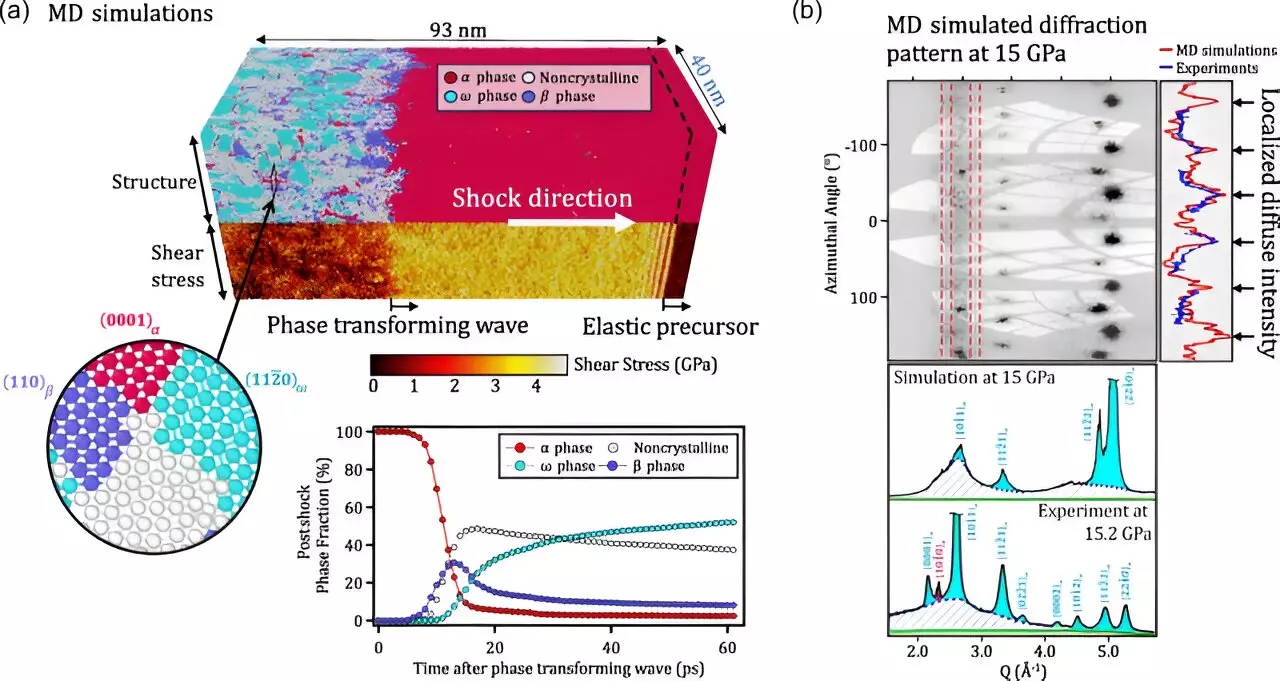

What distinguishes this study from earlier research is the innovative approach employed by the researchers. Using femtosecond in-situ X-ray diffraction, they were able to observe the deformation dynamics of zirconium over nanosecond timescales. This technique unveiled atomic disorder—a phenomenon not observed in elemental metals until now—alongside multiple pathways for structural transformation. Such findings underscore a significant advancement in our understanding of material science, expanding the narrative surrounding the behavior of metals under extreme stress.

Traditional understanding asserts that metals like zirconium deform plastically through dislocation motion—mechanisms where defects within the crystal lattice shift under stress. However, the LLNL research highlights additional factors at play, including crystallographic twinning, shear-induced amorphization, and even phase transitions resulting from pressure changes. The intricate deformation patterns suggest that zirconium exhibits a rich, multifaceted response to external stresses that challenge prior assumptions. Lead author Saransh Soderlind emphasizes that precise knowledge of these mechanisms is crucial for predictive modeling of material performance, particularly as industries push the boundaries of technology.

The implications of these findings extend far beyond zirconium itself. The sophisticated understanding of atomic behavior under strain seen in this study is indicative of similar complexities likely present in a range of materials, which could influence the future direction of material engineering. Given zirconium alloys’ critical role in the nuclear industry as cladding for fuel rods, this research not only enhances our understanding of this specific metal but could also lead to novel techniques and applications in other sectors dealing with extreme environmental challenges.

In sum, the intricate findings concerning zirconium’s behavior at high pressures underscore a transformative period in material science. With ongoing research leveraging innovative methods, the potential for developing advanced materials that can withstand the rigors of modern technology seems brighter than ever.

Leave a Reply